The Need for Metal Detection in Aggregate and Mining

When a piece of metal gets into in your crusher or screen it can cause catastrophic damage. The resulting cost in downtime, labor and repairs needed to get back up and running again can be staggering. While magnets are still a very effective way of removing tramp iron and other ferrous material from a product stream, not all harmful contaminants can be separated by magnets. A piece of metal at the bottom of the belt, buried beneath burden, or a bucket tooth with a high manganese content might be missed by a magnet alone. Scenarios like these are when a metal detector may be helpful in protecting downstream processing equipment.

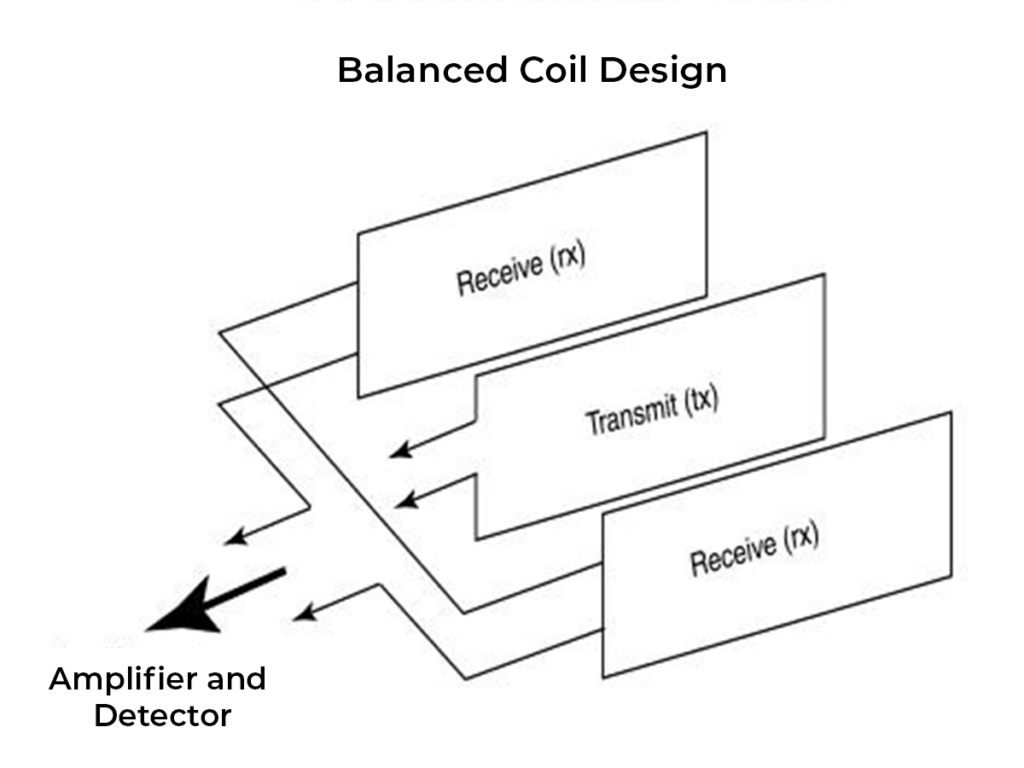

Metal detection is made possible by the fact that all metals are either magnetically conductive, electrically conductive or both. When a metal object traveling along the belt enters an electro-magnetic field, it creates a detectable disturbance in that field or “signal”. Most modern metal detectors are able to sense this disturbance by employing a full loop, balanced coil system. This is created by having a central “transmit coil” broadcasting a specific frequency, flanked on either side by equidistant “receiver coils” tuned to that frequency. Both receiver coils pick up this frequency at the same strength. These signals picked up in the receiving coils are then connected in opposition to each other, resulting in a net zero signal across the coil, creating a balance. The conductive property of the metal object entering the field affects the receiver coil closest to it to a higher degree than the one on the other side of the transmit coil. This breaks the balance. The metal detector’s control electronics amplify and analyze this disturbance, if the signal is greater than an established sensitivity threshold, a detection is indicated.

How to Compensate for Magnetic or Conductive Material

Although the balanced coil system in the metal detector is producing a stable field, there are always outside factors that can upset it in small ways. Some of these factors include nearby electrical equipment, extreme vibrations, and of course, the properties of the material being run on the belt.

Almost all materials have some amount of magnetic permeability or electrical conductivity. This is called “product effect”. While material like limestone can have a very low conductivity, others, like iron ore, can have a substantial product effect. Understanding the innate magnetic and conductive properties of your product will assist you in establishing tramp metal detection standards preventing false trips and production stoppages.

Acculearn: Learns the Product Effect of Your Material Stream in as Short as Two Minutes

When it comes to determining the level of product effect inherent in your material, Advanced Detection System’s Protector series metal detectors come standard with our unique Acculearn feature. While running a material stream representative of your average product flow, the AccuLearn feature captures the product effect signal. After a few minutes of run time, the “LEARN SUCCESSFUL” screen will appear and the Sensitivity Settings will have been established and set. Now the metal detector can accommodate for your product’s signal while still being sensitive enough to detect tramp metal in your product stream.

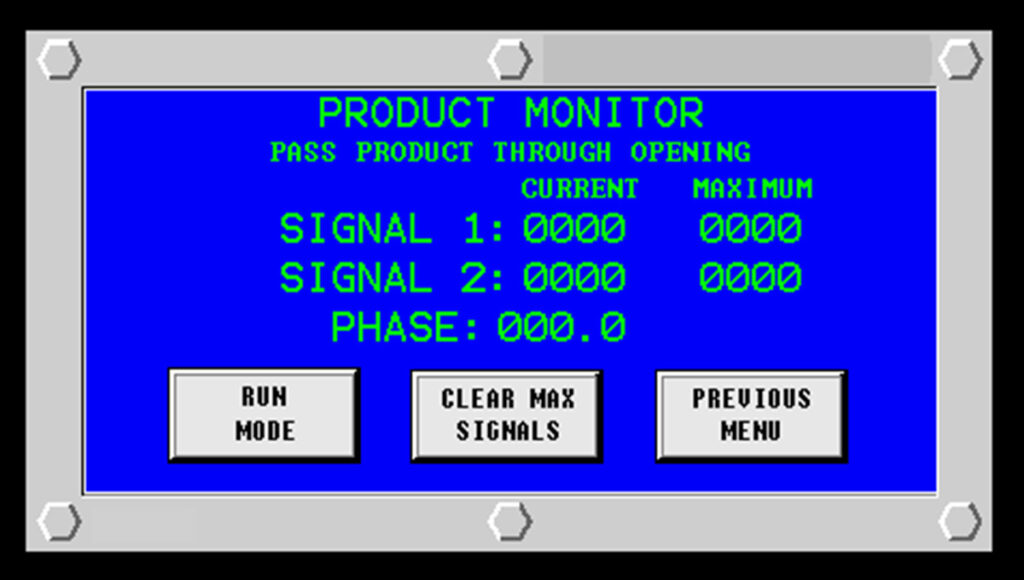

Product Monitor: Real Time Measurements Allows Your Detector to Recognize Which Tramp Metal Can Cause Damage and Which can be Ignored

Not all metal contaminants are problematic. It’s important for your metal detector to be able to tell the difference between a bucket tooth that can damage your equipment and small bolt that can be safely ignored. Advanced Detection System’s Product Monitor feature displays real time values of the product effect and any tramp metal in your product stream. This feature allows your crew to adjust the sensitivity settings in order to ignore small pieces of metal that won’t harm your equipment while still detecting larger, harmful ones. By doing this you can prevent unnecessary production stoppages.

Protector Series: Metal Detectors

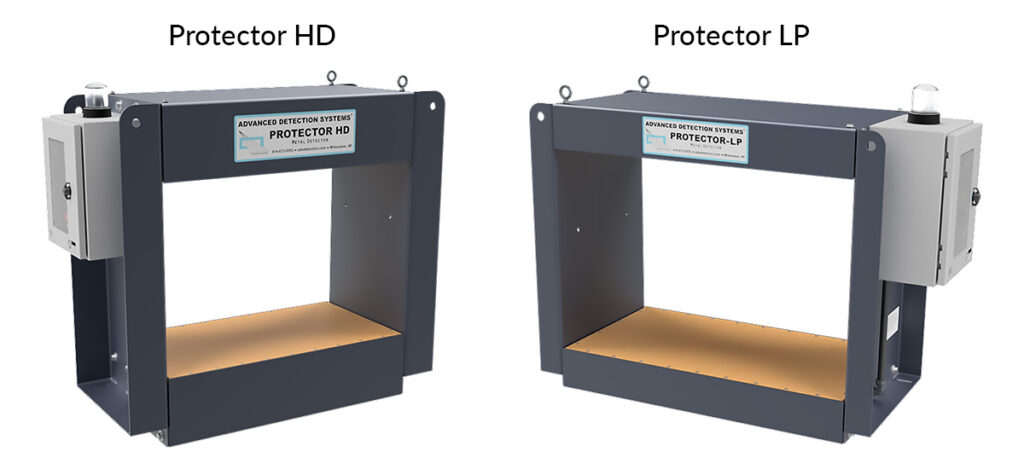

Protector HD

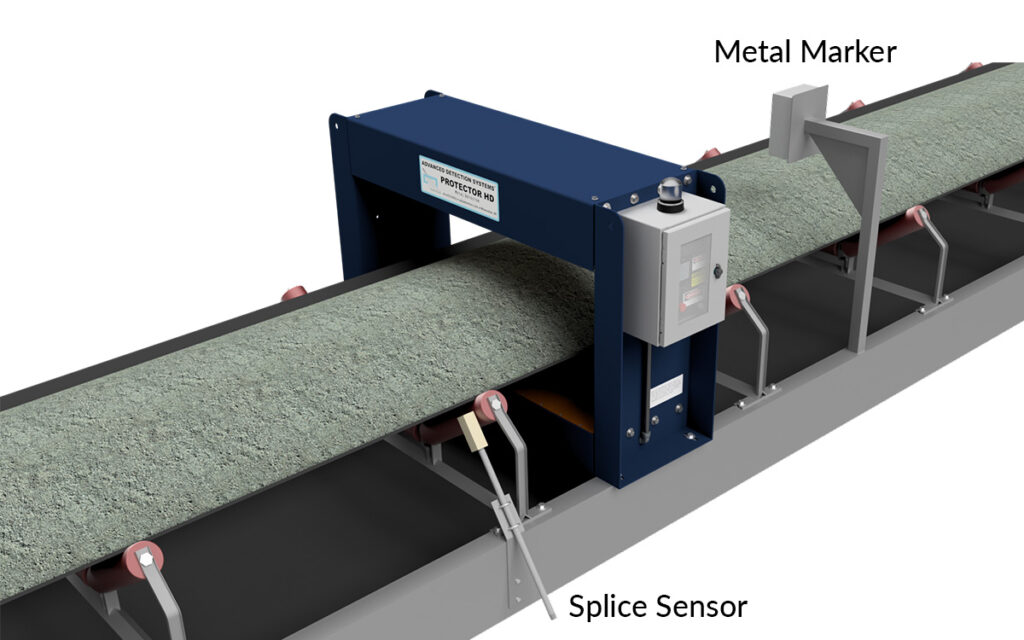

Advanced Detection System’s Protector HD Metal Detectors are constructed of heavy-duty carbon steel allowing them to withstand tough applications and harsh environments others simply cannot. They come standard with the Acculearn and Product Monitor features we discussed today. The Protector series also comes with standard software to help compensate for high vibration environments. All Protector series Metal Detectors are available as a complete system with a metal marker and splice sensor accessories.

Protector LP

The Protector LP comes with all the standard operating features of the HD model with a 45% smaller coil enclosure and a 40% reduction in weight. This reduces the cost and size of the unit which simplifies installation on conveyor frames where clearance between the conveyor belt and frame is limited. Protector LPs are for use on conveyors with belt widths of 48” or less.

SurroundScan Protector; Metal Detection Systems Designed for the Aggregate & Mining Industries

Advanced Detection System’s Protector series metal detectors are rugged, reliable and engineered for performance. The SurroundScan Protector is available separately or as a complete metal detection system with metal marker and splice sensor accessories. To discuss your specific application needs and for help determining the best metal detection system for your process, give us a call at call at (414) 672-0553 or email us at sales@adsdetection.com. Our team can also assist you with a custom industrial metal detection solution for your specific application.