The ProScan Max® III is built to your application specifications and sized to meet your specific needs. Get the best detection results in wet, dry and conductive products by calling us today at 414-672-0553!

These Core Technologies Provide Reliable Metal Detection Performance Required for Today’s Stringent Food Industry Safety Regulations

Setting up products with the AccuLearn Technology is easy and efficient. In as few as 1-2 passes, the metal detector will learn your product’s signature, allowing clean product to pass through while accurately identifying and rejecting products that have metal contamination.

ProScan vibration technology monitors interference created by vibration and automatically compensates for the effect, thus enhancing reliability and sensitivity.

Advanced Detection Systems’ auto-balance software maintains perfect coil balance and optimum performance, eliminating the cost of a service technician plant visit to re-balance the metal detector.

IP69K WASH DOWN DEFINITIONS:

IP: Ingress Protection (the degree of protection provided by the electrical enclosures)

6: Dust Tight

9K: High Pressure/High Temp Spray Down

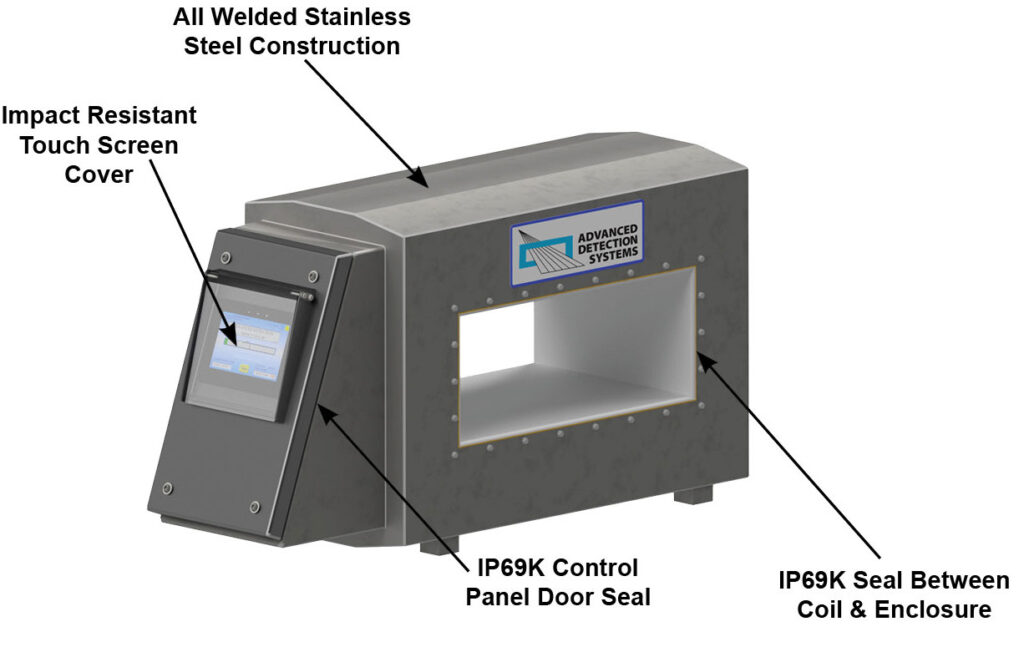

Our ProScan Max® III is rated IP69K for sealing of the electronics and extreme wash down conditions. As a food industry metal detection system, the ProScan Series is designed to withstand high pressure wash down environments. The ProScan Max® III is preferred by food processors because it prevents water from getting into the coil, which is encapsulated with waterproof material. Stainless steel housing is embedded into PVC at a 90° angle – unlike other detectors where water can seep through a vertical seam – resulting in costly repairs.

The welded construction and stainless steel components are designed to provide many years of reliable performance. The seams are sealed under pressure using extra mounting bolts. The sealant acts as a pressurized gasket to form a superior seal against harmful water ingression. The control panel door is sealed to specifications and has an impact resistant touch screen cover. The metal detector can withstand close range wash downs at an average rate of four gallons per minute with water pressures between 1160 – 1450 psi and at a temperature of 176°F.

Advanced Detection Systems’ engineers are experts in metal detection. We manufacture superior reject devices and accessories to meet your application requirements and food industry standards. Any reject device and accessory can be customized or designed to your specific needs.

Reject devices are used to allow the customer to remove contaminated product and most times still maintain normal product flow without halting production. The use of a reject device also allows the company to avoid relying on the employee to remove the contaminated product from the line.

Having a reject device for your ProScan Max® III is important. The reject device will prevent contamination, protect your customers, provide a stellar reputation of your product (brand name) and protect your profits. The product or the package of the product will determine which type of reject would be best for the application.

How to determine which reject device is appropriate for you?

The ProScan Max® III has a variety of reject devices. Most reject devices are shown on the ProScan Conveyor System page.

Advanced Detection Systems offers accessories that can be incorporated into the existing metal detection system as needed to meet your specific needs. Our accessories are beneficial in many ways: accessories protect the product stream, ensure employee safety and optimize operation in extreme temperatures.

Advanced Detection Systems offers accessories that can be incorporated into the existing metal detection systems as needed to meet your specific needs. Our accessories are beneficial in many ways: they protect the product stream, ensure employee safety and optimize operation in extreme temperatures.

The external remote control cabinet enclosure is IP69K rated for washdown environments. They are used when the metal detector is placed in a difficult to read position in your product stream. We also offer external remote control fiberglass cabinets as an option for wipe-down environments.

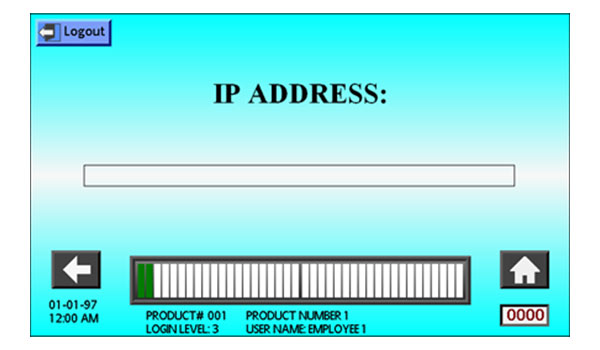

The web-enabled touchscreen allows the metal detector to be connected to a local network. The metal detector can be monitored and controlled remotely from any device with an internet browser (your device must be connected to the same network as the metal detector).

The web-enabled touchscreen makes data collection easier by allowing the data-log files to be downloaded directly to a computer. The ability to monitor, control and review data requires no additional proprietary software.

Metal detectors used in environments below 40°F (4°C) should be equipped with a cabinet heater to reduce condensation buildup and prevent the LCD screen from becoming lethargic or difficult to read in cold temperatures. The cabinet heater has a built-in thermostat to regulate temperature.

We will welcome your call when you need advice from metal detection experts for food processing and industrial applications

Copyright All Rights Reserved © 2024 | Website Design by Matt Gerber Designs | Terms & Conditions | Privacy Policy