The ProScan line of metal detection systems are designed for use in food industry applications where high-sensitivity is required. ProScan Systems sensitivity to metal is measured in tenths of a millimeter. All ProScan metal detectors can detect ferrous, non-ferrous and stainless steel metals. They will detect metal fragments like knife blade chips, broken screen, needles, filings and other fractionally-sized metal contaminants.

Each ProScan metal detector is sized for specific application requirements and configured based on the type of product passing through the detector.

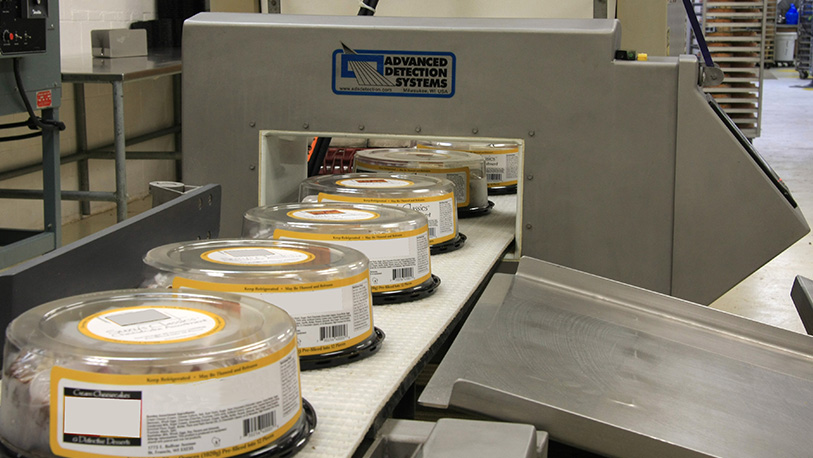

Conveyor mounted metal detection systems are typically used for solid or packaged food products where a conveyor belt moves the product through the metal detector.

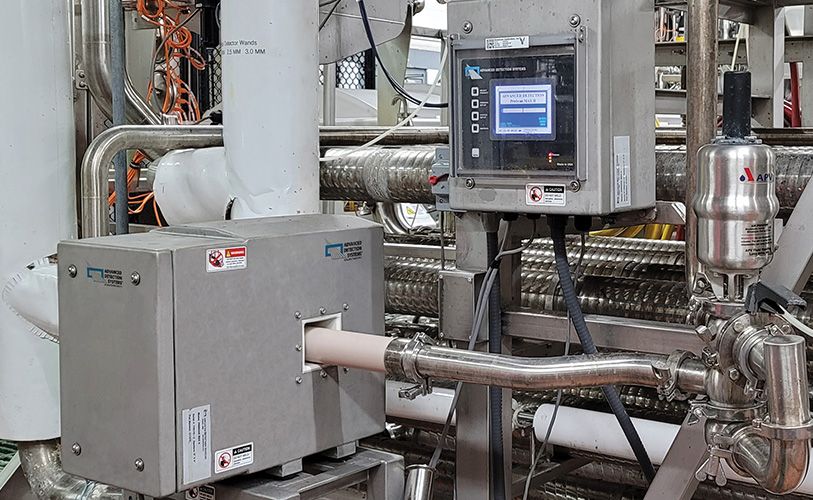

Pipeline metal detection systems are designed to be mounted around a metal-free pipe that product is pumped through.

Gravity Drop metal detection and rejection configurations are mounted vertically to inspect free-falling product prior to packaging.

All ProScan metal detector systems are constructed of 304 stainless steel with an IP69K heavy washdown rating. The principles of operation are the same for all ProScan metal detection systems regardless of the configuration.

Discuss your application with an Advanced Detection Systems metal detector expert today to determine what is the best configuration for your application.

Give us a call at (414) 672-0553 or email us at: sales@adsdetection.com.

We will welcome your call when you need advice from metal detection experts for food processing and industrial applications

Copyright All Rights Reserved © 2024 | Website Design by Matt Gerber Designs | Terms & Conditions | Privacy Policy