For nearly 25 years, Advanced Detection Systems has been providing metal detectors for the food processing, packaging, pharmaceutical, nutraceutical and industrial applications.

The ProScan Max® III conveyor metal detector system is ideal for running packaged and some larger loose products. However, when it comes to free-flowing granule sized products or pumped viscous liquid and semi-liquid products that need metal detection, a conveyor system may not be the best option. That’s where ProScan Max III gravity drop and pipeline metal detectors come in.

Metal Detectors for Free Flowing and Pumped Product

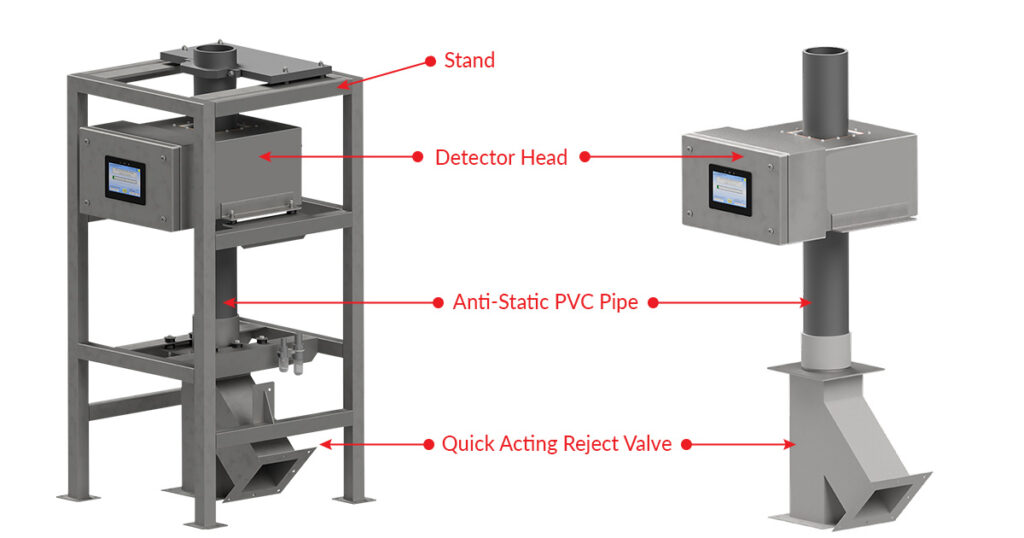

Gravity Drop Metal Detection for Free-Flowing Product

The ProScan Max® III Gravity Drop System metal detector is an ideal solution for detecting metal in free-flowing bulk granular or powdered food or nutraceutical products. In gravity fed metal detection systems, product is dropped into an anti-static PVC tube that runs through the metal detector’s aperture. The anti-static tube prevents buildup of powdered or fine grain products. If metal contamination is detected a fast acting divert valve is activated, removing the contaminated product. This method is often used upstream of the filling process if the product’s end packaging is not compatible with metal detector inspection. Another benefit of using this upstream method is that any size package can be filled while maintaining a high level of metal detection sensitivity.

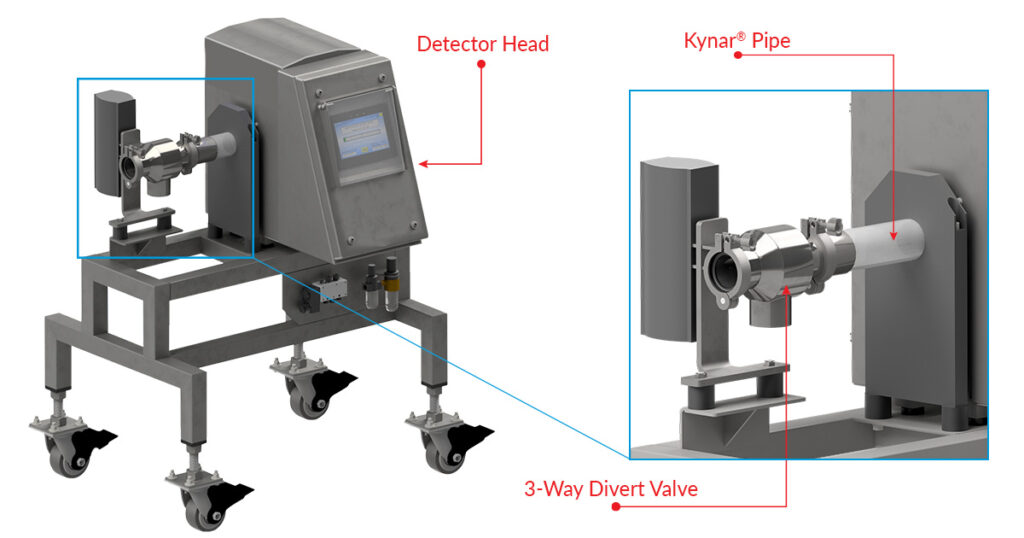

Pipeline Metal Detection for Pumped Viscous Product

The ProScan Max® III Pipeline System metal detector is space efficient and ideal for ice cream, soft cheese and ground meat food processing and packaging applications. In pipeline metal detectors, viscous product is pumped through a high strength Kynar® pipe that runs through the metal detector’s aperture. The Kynar® tube is pressure and heat resistant making it ideal for hi-temperature and pressure washdown applications while still being invisible to the metal detector. When metal contamination is detected a 3-way divert valve is activated, removing contaminated product sanitarily and easily. Pipeline metal detection systems are often used to inspect pumped food products that are canned or deposited in containers that are closed with, or have, conductive components.

Features of ProScan Max® III Metal Detectors

Advanced Detection Systems’ ProScan Max® III metal detector systems have several standard features making them the choice of many food packaging companies.

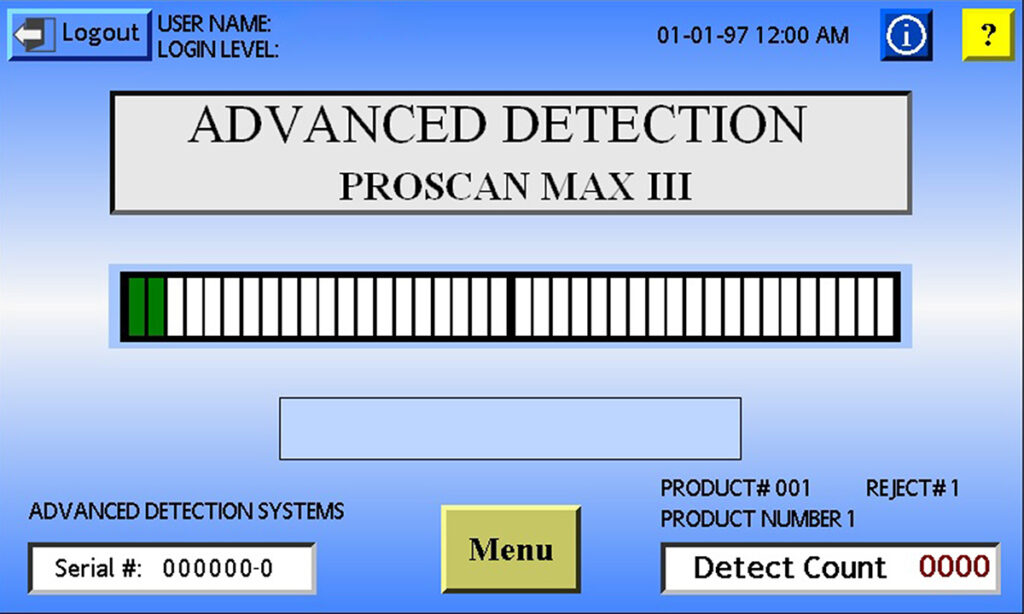

ProScan Touchscreen

The ProScan touchscreen comes installed with Intuitive software and controls that are easy to navigate allowing the user to make quick changes to the metal detection system without disrupting production. Two separate password restricted control levels for administrative and basic operators record the user name, time, and date of each event. This creates a running list of recent detection events visible from the menu or on the web and downloadable as an excel document.

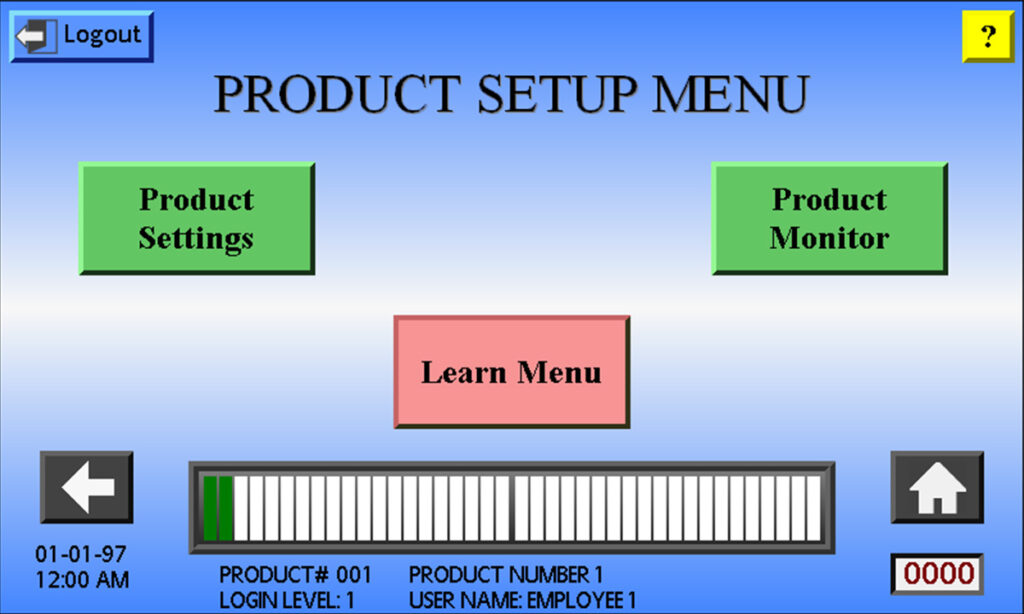

ProScan Acculearn & Product Monitor Technologies

Acculearn Technology allows our metal detection systems to learn your product’s characteristics in as few as two passes. This automatically sets the metal detector to proper sensitivity levels, eliminating false trips caused by product variability while ensuring any metal is detected.

The Product Monitor feature displays real time values of the product’s signature and Enhances the operator’s ability to adjust detector sensitivity settings for optimum, reliable performance

Metal Detection Systems for Food Processing & Packaging from Advanced Detection Systems

Food processing and packaging applications require metal detection systems well suited to your specific process and product. We manufacture a variety of metal detection systems, including conveyor systems, pipeline systems, and gravity drop systems, designed to protect product purity and increase efficiency. Each metal detection system is custom designed and built to fit your specific food processing or packaging needs. Give us a call at (414)672-0553 or email mailto:sales@adsdetection.comto get the best detection results in wet, dry and conductive food.