Metal Detection for Aggregate & Mining Applications

In industrial applications, metal detectors defend production lines from tramp metal and ferrous impurities that can damage your conveyors and processing equipment. Proper use of an industrial metal detector also improves the purity of your product. Today we’ll discuss three different optional accessories that will make your metal detector more efficient and easier to use.

Splice Sensors Aid in Industrial Metal Detection

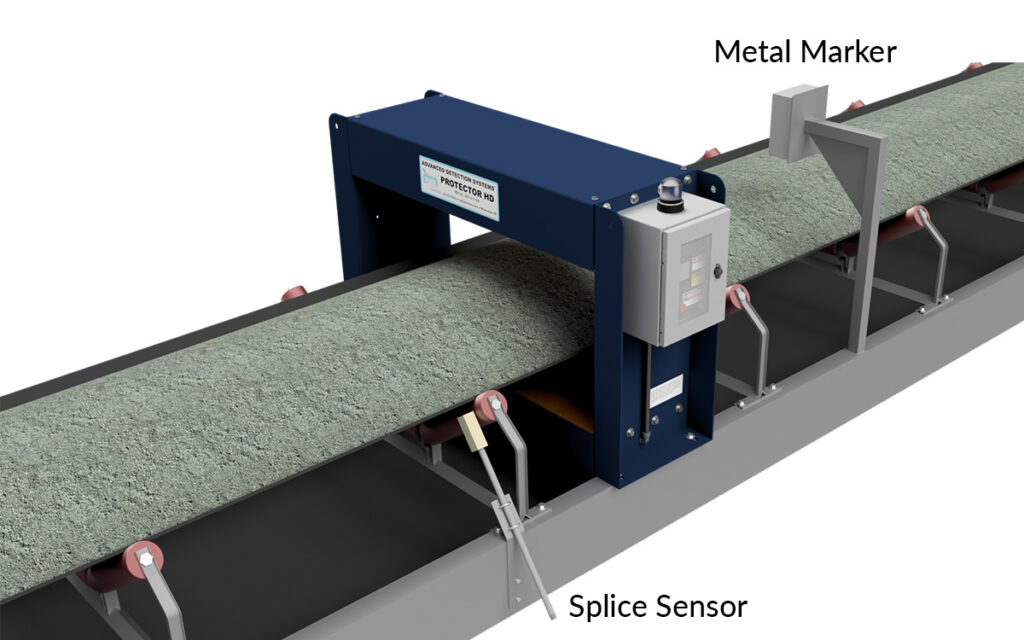

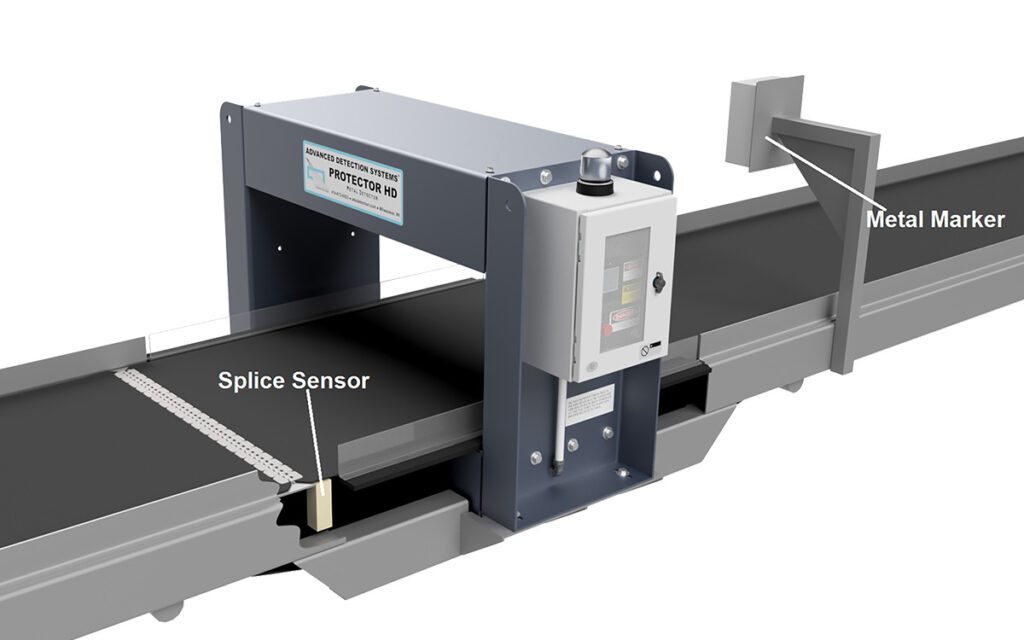

Splice sensors are an optional accessory for our industrial metal detection systems. They allow conveyor belts that have metal splices and repair clips to be used to carry product through a metal detector. Metal splices are typically used on conveyor belts in industrial settings such as quarry and mining applications as well as plastics and corrugated recycling to connect two ends of a belt together to form a continuous band. Spliced belts are more economical and easier to maintain option in comparison to an endless belt.

How Splice Sensors Work with Metal Detectors

The splice sensor detects the metal splice as it passes by and sends an electronic signal to the metal detector reducing its sensitivity enough to allow the belt splice to pass while still detecting the incremental signal of metal that could be in the material on top of the splice. The metal detector settings used to accommodate the splice are established at the initial start-up of the metal detector. While material is being conveyed through the detector it’s Splice Auto Learn feature is used to create the splice sensitivity setting and duration required to accommodate the splice while it’s traveling through the detector’s metal free zone.

Metal Markers; Make Finding Tramp Metal on Your Line Fast & Easy

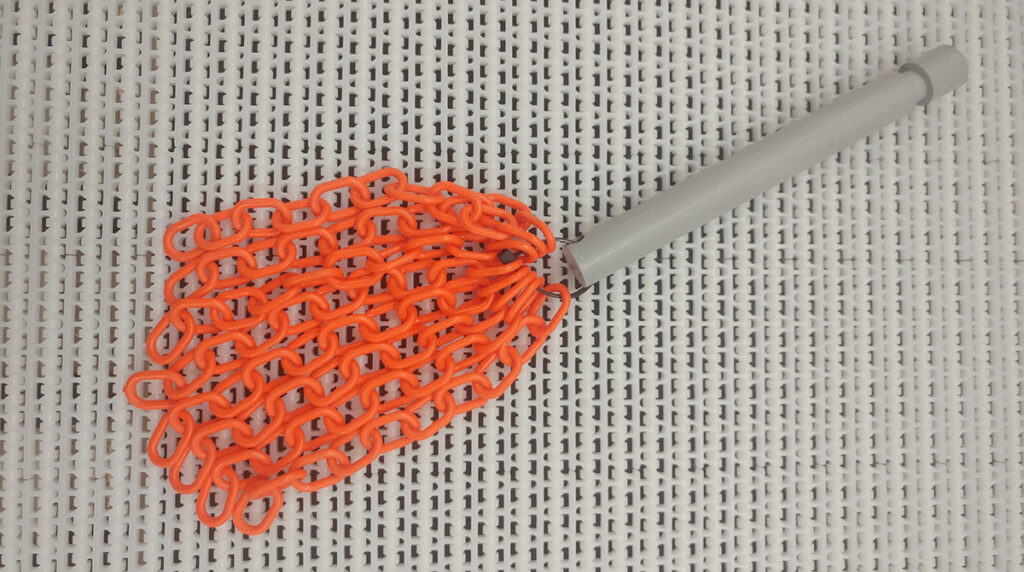

Metal markers are another metal detector accessory often used by the aggregate and mining industries. On conveyor belts greater than 4 feet wide and carrying a deep burden, it can be difficult to locate tramp metal that’s been detected. Metal markers are used in conjunction with the metal detector to mark the location of the ferrous, non-ferrous or stainless-steel metal that has been detected. The metal marker simplifies and reduces the time required to locate and remove the tramp metal.

How Metal Markers Work with Metal Detectors

When tramp metal is detected by the metal detector it actuates the metal marker device, dropping a high visibility marker at the location of the tramp metal and stopping the conveyor. The dispensed marker helps the operator locate the metal that must be removed from the conveyed material before the conveyor is powered up again. The detection, marking and removal of tramp metal is a critical line of defense in preventing damage to industrial processing equipment and costly downtime.

Remote Control Cabinets Grant Ease of Access

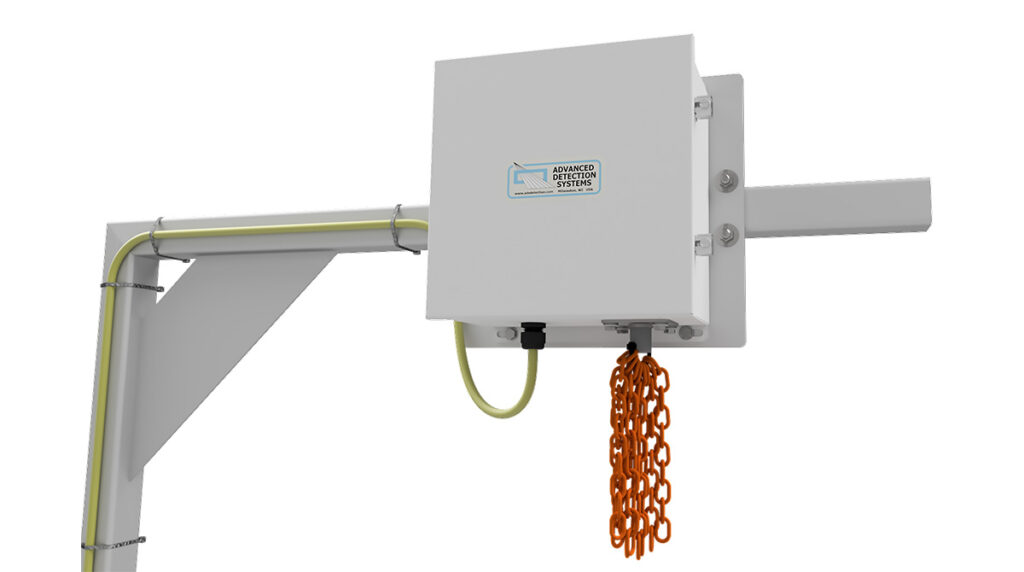

If the metal detector is installed in an area that is difficult to access, such as an inclined conveyor without foot access, a remote control cabinet can be used. The Advance Detection Systems remote control cabinet is constructed of NEMA 4X rated fiber glass that’s resistant to corrosion as well as windblown rain and dust, making it suitable for many industrial applications. Standard cord lengths of 25 & 50 feet allow the metal detector to be fully operated from a location of your choosing.

SurroundScan Protector; Metal Detection Systems are Designed for Industry

Advanced Detection Systems’ Protector metal detection system is rugged, reliable and engineered for performance. The SurroundScan Protector is available as a complete metal detection system with all the features we spoke of today. To discuss your specific application needs and for help determining what is the best metal detection system for your process, give us a call at call at (414) 672-0553 or email us at sales@adsdetection.com. Our team can also assist you with a custom industrial metal detection solution for your specific application.