Metal Detector Verification is a crucial and most often required part of ensuring the purity of your product and protecting your business. Read on to learn more about metal detector verification, how it’s conducted, how it differs from validation and why it’s so important to your business.

What is Metal Detector Verification?

Food production facility metal detectors are tested multiple times during production to ensure they are always properly detecting and rejecting contaminated product as required by the owner’s critical control point documentation. The daily tests and record keeping are usually performed in-house by quality control personnel. This confirmation of a metal detector’s ability to meet the standards set forth by its owner is referred to as Validation.

Verification of those tests are done by an outside company that visits your plant and performs the same daily tests the metal detector’s owners do while also ensuring proper testing practices are used. If the metal detector passes the tests as required by the equipment owner, just like it does during the production run tests, the detector is considered verified. The test result records done by the food company on a daily basis are verified to be accurate based on the same results being achieved when an outside company performs the same tests. If the outside company is not able to get the metal detector to meet the specified test results, the detector cannot be verified and the metal detector’s settings or methods of testing need to be reviewed and corrected so it can meet the standards required by the owner’s documentation.

Why Metal Detector Verification & Documentation?

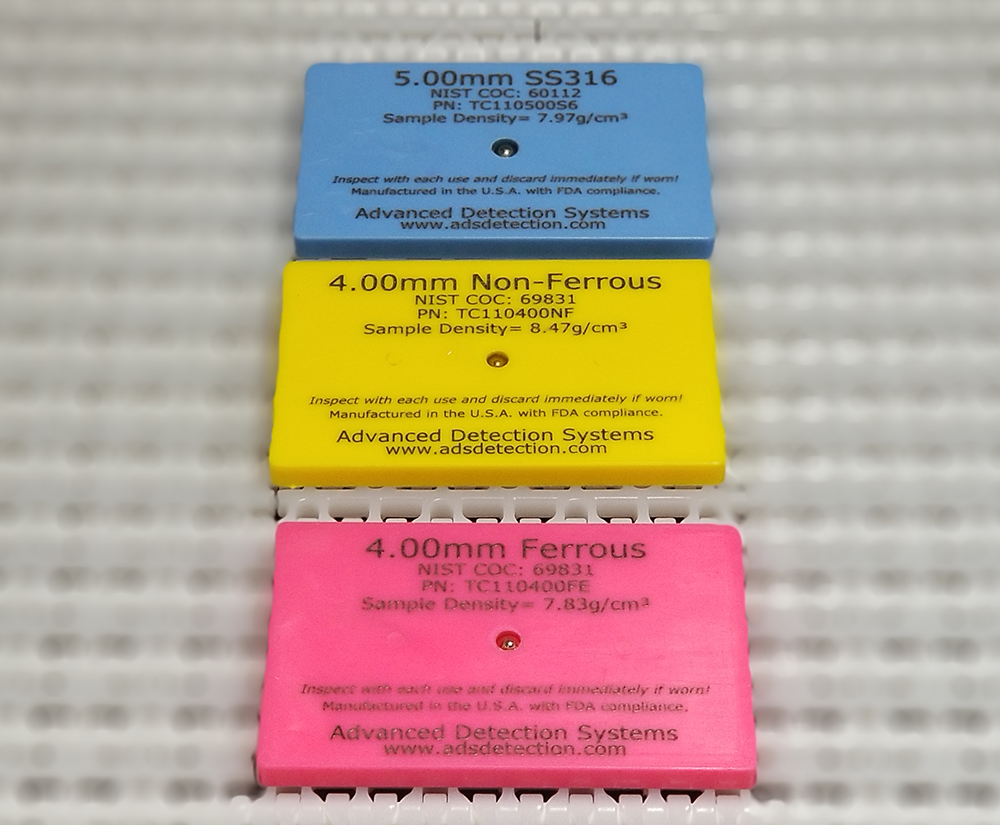

Verification service is conducted to confirm and document the metal detector in service is detecting Ferrous, Non-Ferrous and stainless steel particles of a specified millimeter diameter without false tripping on the product in production. If the metal detection system in service has an automatic reject device the rejection of the detected metal particle is also confirmed and documented.

Metal Detector Verification & Food Safety Plans.

Documented Metal Detector Verifications are key components of a food processors food safety plan. Regularly scheduled Verifications conducted by a 3rd party help ensure the purity of a company’s product and provide protection of a company’s brand. Verifications are required by government regulations, auditors, Hazard Analysis Critical Control Point (HACCP) plans and most food retailers.

How Is Metal Detector Verification Service Conducted?

Metal Detector Verifications are typically scheduled annually and conducted by metal detector manufacturers and their Certified representatives. Verification is conducted by passing Ferrous, Non-Ferrous and Stainless Steel certified test wands under normal production conditions through the center of the metal detector aperture a minimum of three times each. Successful detection and rejection of the test wand and product are documented and Verification stickers are applied to the metal detector by the person conducting the Verification.

Have Your Metal Detection System’s Performance Verified by ADS

Advanced Detection Systems conducts Verification on any make/model metal detection system or equipment. Our HACCP (Hazard Analysis and Critical Control Points) certified factory service technicians and certified local representatives conduct metal detector verifications on-site and are compliant with most QA programs, audits, HACCP and GMP (Good Manufacturing Practices) standards. Contact us at 414-672-0553 or service@adsdetection.com to schedule Verification services you need today!