How Metal Detectors are Used in Food Processing

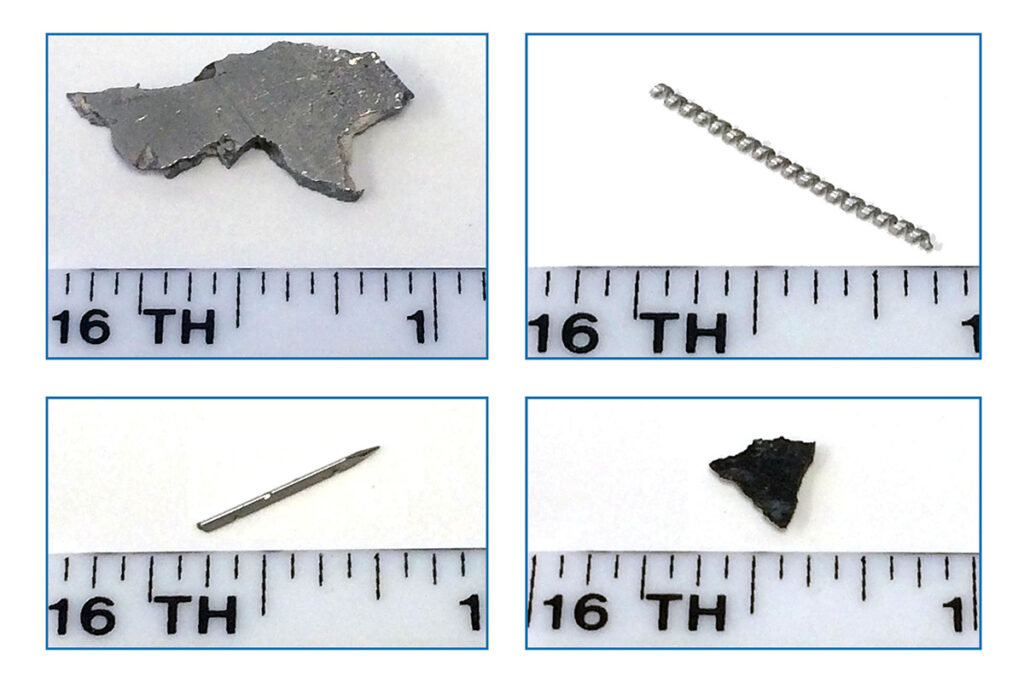

Introduction of metal contaminates can result from a variety of breakdowns common in the production process. Anything from processing equipment wear and tear, environmental hazards, to the harvesting of the product. Regardless of the source, metal must be removed to protect your customers, your equipment and your company’s reputation. Conveyor mounted metal detectors are a common solution. However, when it comes to selecting the right one for you, that depends on your specific application needs.

Metal Detector Systems for Washdown Environments

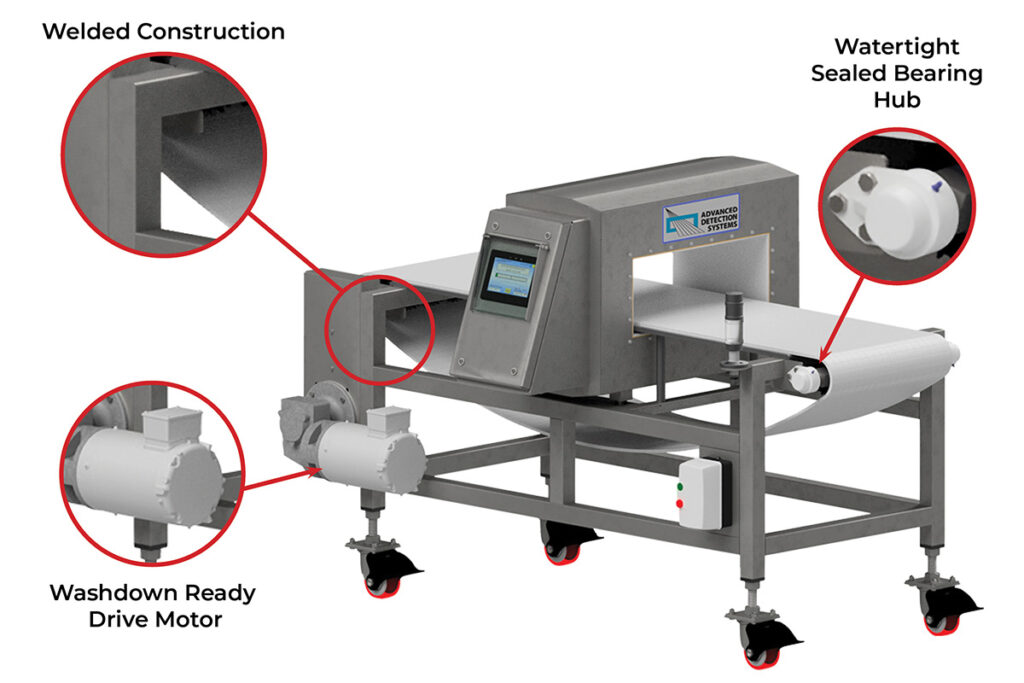

Some applications, like meat processing, require stringent hygiene standards to prevent bacterial and other pathogenic contamination. The best way to accomplish this is through a rigorous washdown procedure. In order for this to take place your metal detector conveyor system can’t have joints or crevasses hiding organic residue that can be contaminated. Areas where water can accumulate, like in between the joints on a bolt- together conveyor frame, are also unsanitary. This is where a seamless welded conveyor frame is ideal.

Welded Frame Conveyor Metal Detectors

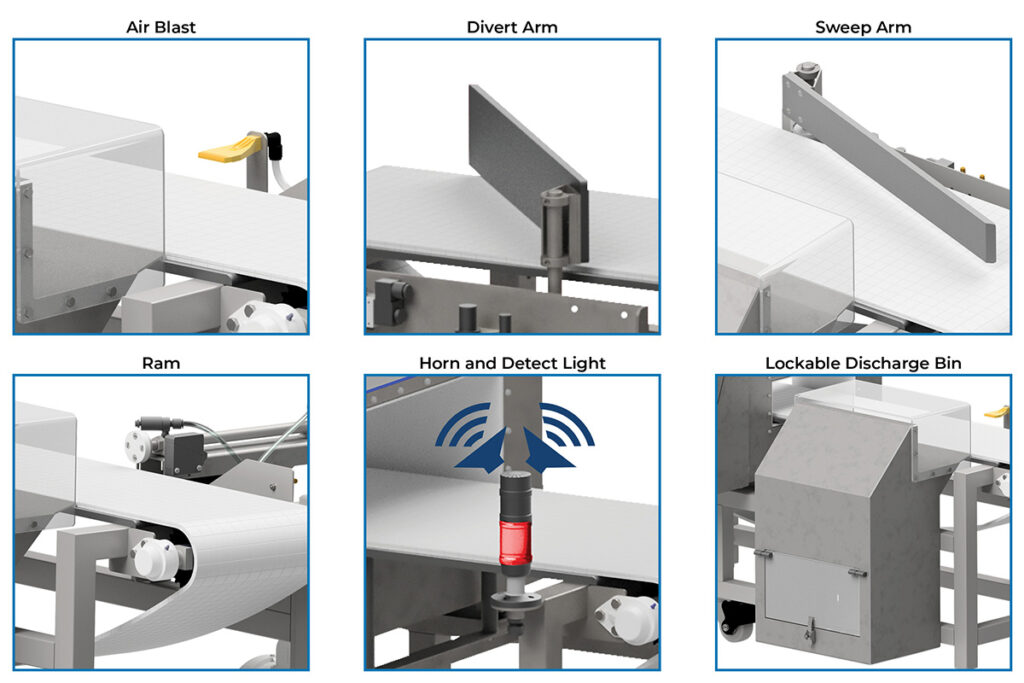

Our heavy-duty welded conveyor is constructed of bead blasted 304 stainless steel that is resistant to corrosive and wet environments. This includes those found in high pressure washdown procedures. Our metal detector conveyors are designed for bulk, packaged and big bag applications. Conveyor frame heights are tailored to your specific needs. Horizontal and incline construction is available. Multiple belt widths and lengths are offered. Welded frames can accommodate a wide variety of automatic reject devices including some not available on bolt-together models.

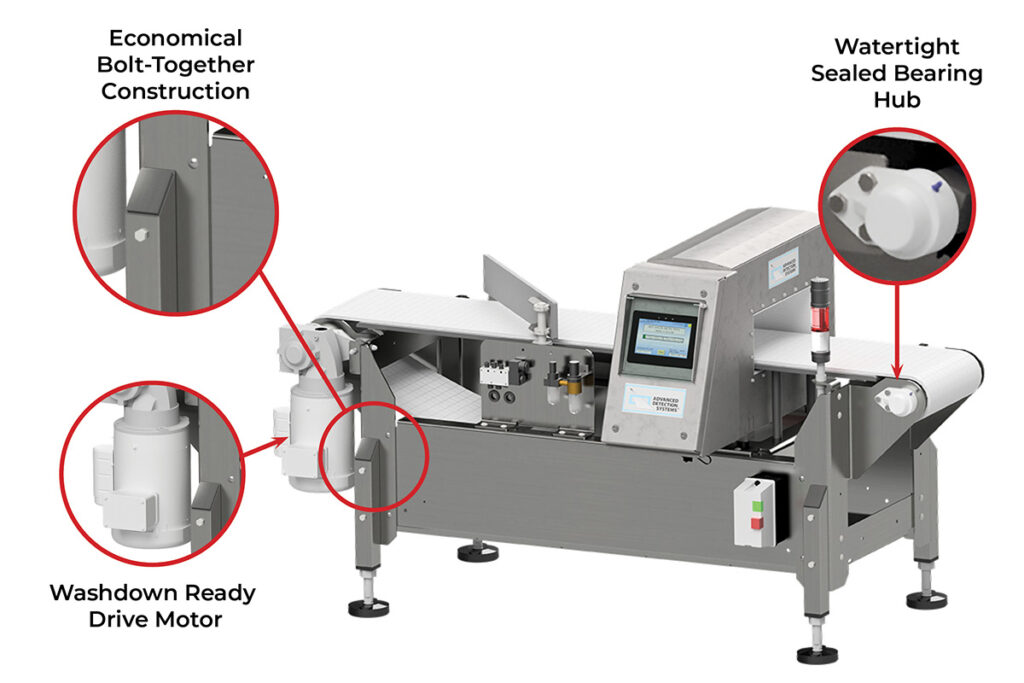

Metal Detector for Packaged and Dry Products

For applications such as sealed packaged products, washdown sanitation of equipment may not be as common in the inspection phase of the process. In these scenarios, the added cost of a custom-built welded conveyor may not be necessary. Packaged or dry applications can benefit from using a more cost-effective bolt-together metal detector conveyor. These are most often built in standard sizes making them more readily available reducing lead time.

Bolt-Together Frame Conveyor Metal Detectors

Advanced Detection Systems’ bolt-together conveyors are a sturdy and economical option if your process involves dry or packaged products. Constructed of 11-gauge 304 stainless steel, our conveyors are resistant to both wet and caustic environments. Bolt-together conveyors are available in standard sizes from 48” to 96” long. A variety of automatic reject devices can be incorporated into the conveyor design to meet your specific application needs.,

Industrial & Food-Grade Metal Detectors from Advanced Detection Systems

Advanced Detection Systems has developed a reputation built on 35 years of manufacturing high quality, reliable metal detection equipment for a variety of food processing and industrial applications. With engineering, manufacturing, sales and customer service staff working side by side in our Milwaukee, WI USA facility we can provide prompt, expert advice. We’re here to help, call us at (414-672-0553) or e-mail sales@adsdetection.com to discuss your application details and metal detection need