Determining the proper height and width of your metal detector ensures that your application is getting the best possible sensitivity; both height and width play critical roles in sensitivity and ease of installation.

The Protector metal detection system is designed to fit rails utilizing standard CEMA-approved rollers. In most instances, the detector will drop directly between the rails and no modification is required other than the drilling of mounting holes

Installing the Protector on a new conveyor system.

However, due to the removable endplate, the belt does not have to be removed to install on an existing conveyor system.

Metal Detector Aperture Widths

With that in mind, the Protector HD Metal Detector is built specifically to standard belt widths, and the aperture width of the detector is always 6 inches greater than the belt width. This provides 3 inches of space on each side of the belt to prevent unwanted contact with the metal detector.

Metal Detector Aperture Heights

Determining aperture height is a bit more complicated, as it depends upon variables that are outside of the physical constraints of the metal detector and conveyor. When determining the aperture height of your Protector HD, the following must be considered:

- Trough angle of the belt

- Lump size of the product

- Burden depth of the product

- Bulk Density of the product

- Sensitivity specification

Let’s take a closer look at some of these.

Trough Angle

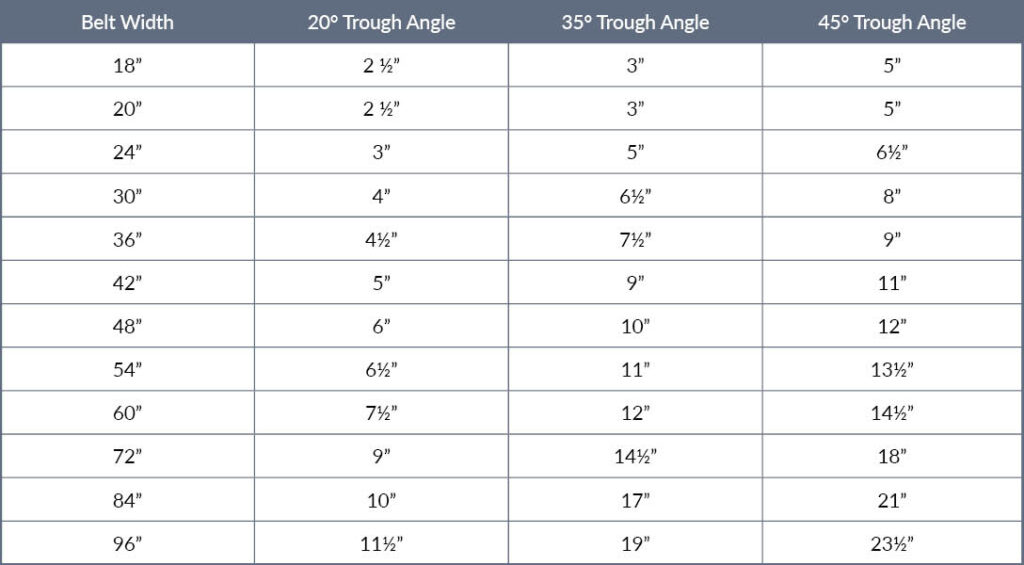

When a belt is troughed, it adds height to the dimension of the belt. This is a constant, so the chart below will provide you with belt heights based on the troughing angle.

Burden Depth

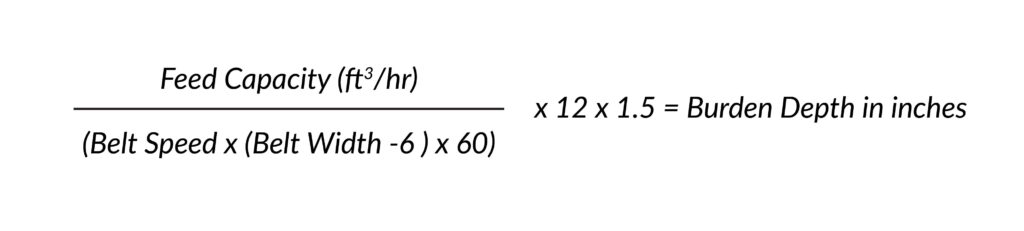

Burden depth is also considered a User Variable – it is determined by the user – but plays an important role in determining the aperture height of the metal detector. In most instances burden depth can be determined by simply measuring the depth of the product at the center of the belt. In the case of new applications, burden depth can be calculated using the following:

- Conveyor belt width in inches

- Conveyor belt speed in feet per minute

- Feed rate in tons per hour

- Bulk Density (specific weight) in pounds per cubic foot (see Bulk Density chart)

- Feed Capacity (ft3 per hour) : Tons per hour ÷ bulk density x 2000 = ft3/hr

Formula to calculate Burden Depth in inches:

Calculating Aperture Height

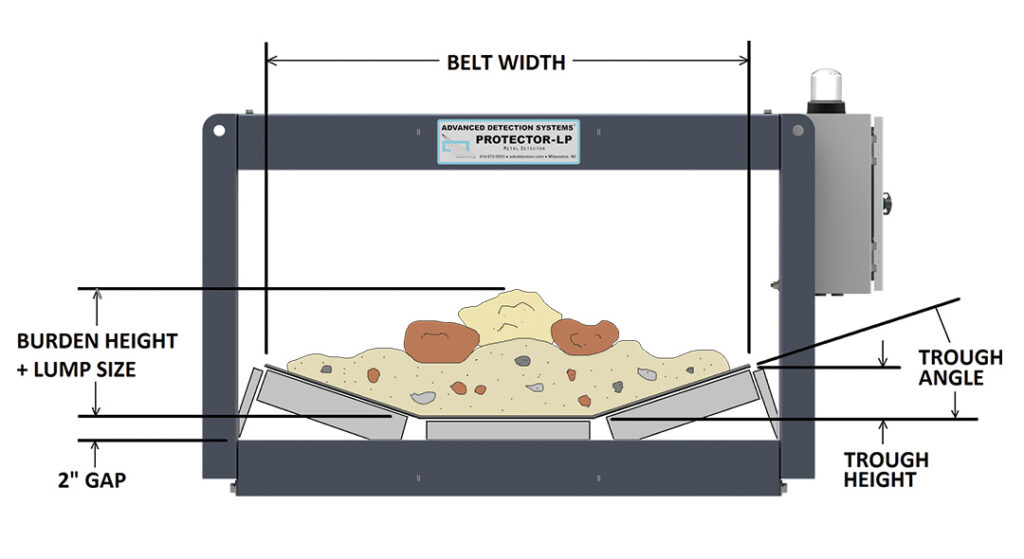

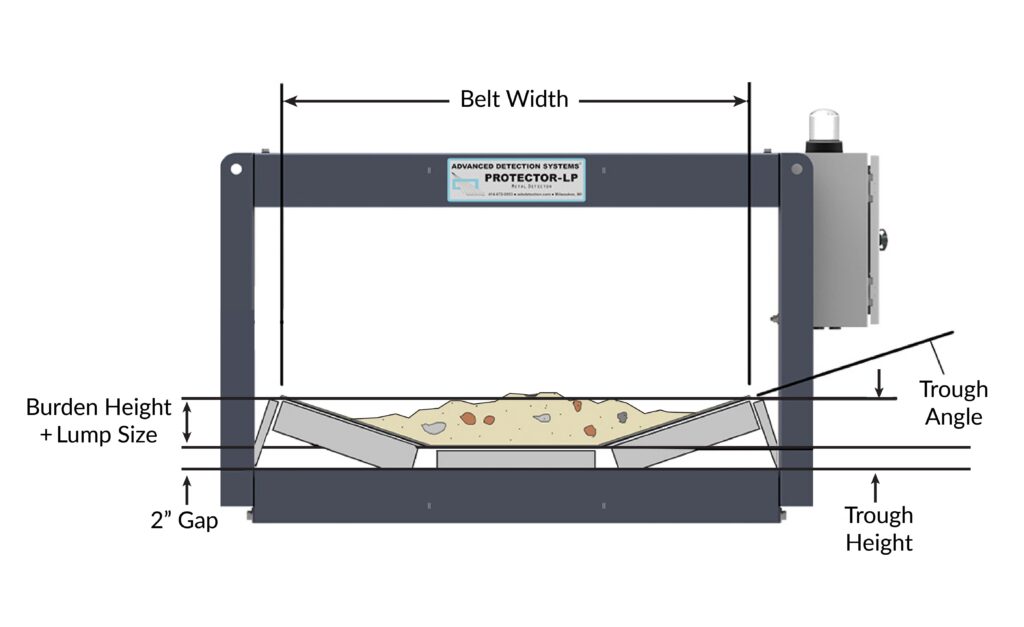

To calculate the aperture height of your metal detector, several factors must be considered.

- Is your burden depth + lump size larger than your trough angle height?

- Is there belt sag as a result of heavy burden on the belt?

- Do I have a specific sensitivity specification?

If your lump size + burden depth value is less than your trough height, use trough height plus 4” to determine your aperture height.

If your lump size + burden depth value is larger than your trough height, use your lump size + burden depth value plus 4” to determine aperture height.

Available Aperture Heights

The Protector Metal Detector is available in the following standard aperture heights (six-inch intervals): 12”, 18”, 24”, 30”, 36”, and 42”. Please contact our team if your height requirements are smaller than 12” or larger than 42”.

After determining your required aperture height, match your number to the closest available aperture height. The shorter the aperture height, the more sensitive the metal detector will be. If sensitivity is critical, please contact us for a review of the application and a quote.

Get the Right Size Metal Detector for Your Application

Advanced Detection Systems’ Protector HD metal detection system is rugged and reliable but to get the best detection sensitivity you need the right size metal detector. Having the proper height and width will also ensure a simple installation. To discuss your specific application needs and for help determining the correct aperture height or width for your metal detector, give us a call at call at 414-672-0553 or email us at sales@adsdetection.com Our team can also assist you with a custom metal detection solution for your specific application.

© 2023 Advanced Detection Systems, Inc. (414) 672-0553