One of the more important factors in determining what metal detector is best for your application is your product and the effect it has on the metal detector. Products have varied levels of conductivity and the conductivity of your product will influence the signals picked up by the metal detector. We call this Product Effect.

What is Product Effect?

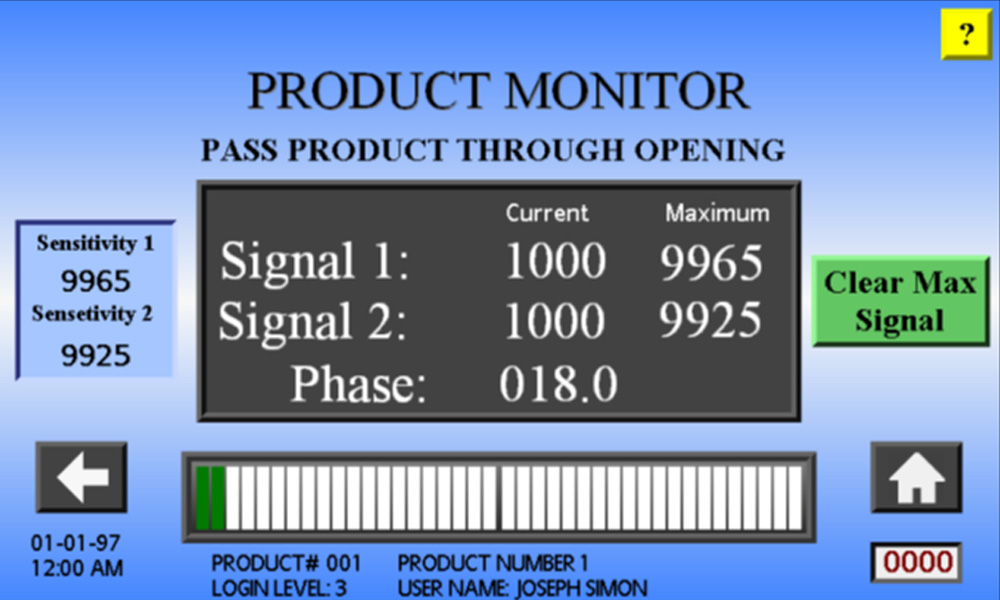

The term Product Effect is used to describe the signal generated by product as it passes through the metal detector. Metal detectors measure the conductivity of things that pass through their aperture. The conductivity of a product is determined by its ingredients. Products that contain salt, fat, minerals, and moisture will be more conductive and generate more product effect than dry products that are less conductive. The signal from these conductive products is accommodated by operating the metal detector at a specific frequency and sensitivity settings that allows the conductive product to pass through the metal detector undetected while still detecting the high-intensity conductive signals of Ferrous, Non-Ferrous and Stainless-Steel contaminants.

Accommodating for Product Effect in Metal Detection

The adjustment of the metal detector made to accommodate product effect, (referred to as phasing out the product) leads to reduced metal detection levels in conductive products when compared to the detection levels achieved in dry products that have little or no product effect. Given the existence of product effect and the need to achieve the best possible metal detection levels, dry products have come to be known as easy metal detector applications while conductive products are considered challenging applications. While this challenge is being met by the continued development of metal detector technology that improves metal detection levels in conductive products, it is possible to enhance detection levels by presenting conductive product to the metal detector in ways that reduce the impact of its Product Effect on metal detection levels.

How to Improve Metal Detection for Conductive Product

Companies processing conductive products such as cheese, pickles, and marinated meats often consider the following methods of improving metal detection levels when developing their process for producing the product.

- Identify Best Possible Product Orientation

- Control Product Orientation

- Control the Consistency of Moisture Level, Product Temperature, Package Size, and Weight.

The Value of Metal Detector Product Testing

The product testing service offered by metal detector manufacturers can be used up front to determine the conductivity of your product and the benefit of controlling product orientation, temperature and moisture level to achieve the best possible Ferrous, Non-Ferrous and Stainless-Steel detection levels.

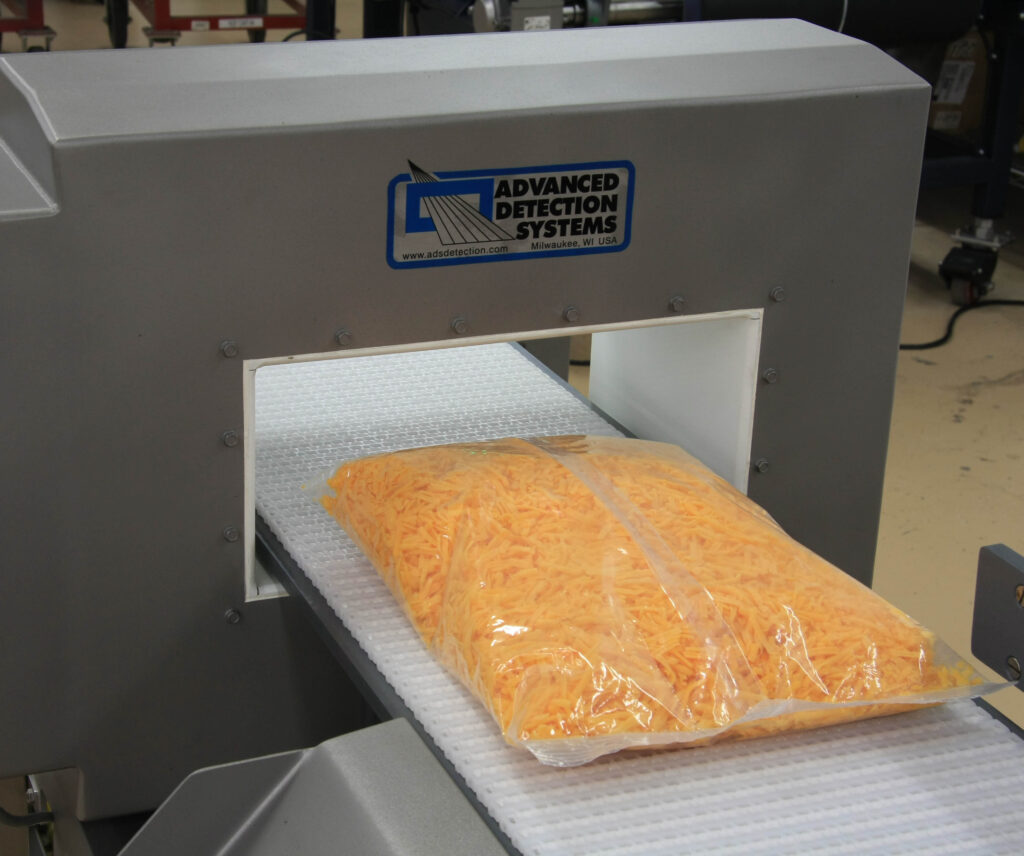

Get the Best Metal Detector for your Application with ADS

Use Advanced Detection System’s free product testing service to ensure that you are investing in the best possible metal detector for your application. Product testing is conducted promptly at our factory lab in Milwaukee, WI and will provide you with a Metal Detection Sensitivity Guarantee indicating the optimal ferrous, non-ferrous and stainless steel detection levels for your specific products in the metal detector aperture size you will be using in your process.

Call us today to get started 414-672-0553 or email us at service@adsdetection.com.