The Protector HD is built to your application specifications and sized to meet your specific needs. Get all the advantages of the Protector HD by calling us today at 414-672-0553!

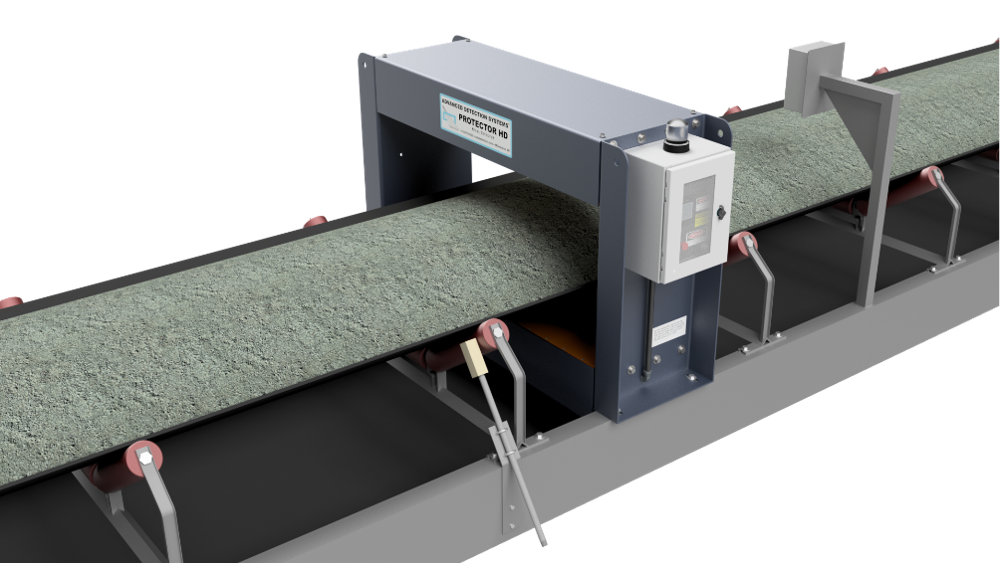

These Core Technologies Provide Reliable Metal Detection of Ferrous, Non-Ferrous and Stainless Steel Tramp Metal Required to Protect Processing Equipment and Ensure Product Purity

Setting up products with the AccuLearn Technology is easy and efficient. In as few as 1-2 minutes, the metal detector will learn your product’s signature, allowing clean product to pass through while accurately identifying and rejecting products that have metal contamination.

With Product monitor, you get real time signal values for your product and the tramp metal that must be detected.

Advanced Detection Systems’ auto-balance software maintains perfect coil balance and optimum performance, eliminating the cost of a service technician plant visit to re-balance the metal detector.

ProScan vibration technology monitors interference created by vibration and automatically compensates for the effect, thus enhancing reliability and sensitivity.

Advanced Detection Systems’ engineers are experts in metal detection. We manufacture superior accessories to meet your application requirements. Any accessory can be customized or designed to your specific needs.

Advanced Detection Systems offers accessories that can be incorporated into the existing metal detection system as needed to meet your specific needs. Our accessories are beneficial in many ways: accessories protect the product stream, ensure employee safety and optimize operation in extreme temperatures.

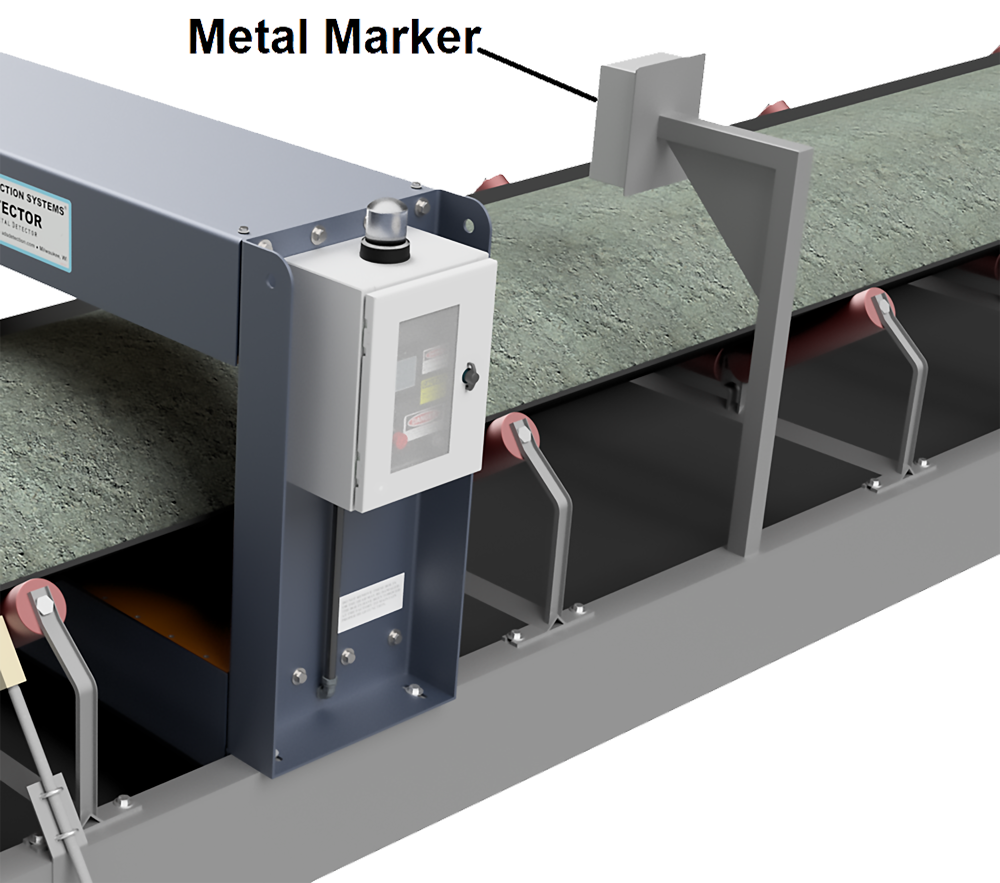

The SurroundScan Protector HD uses metal markers that mark on the belt where metal is detected.

The metal marker is an optional accessory used to mark on the belt when tramp metal has been detected in your product stream.

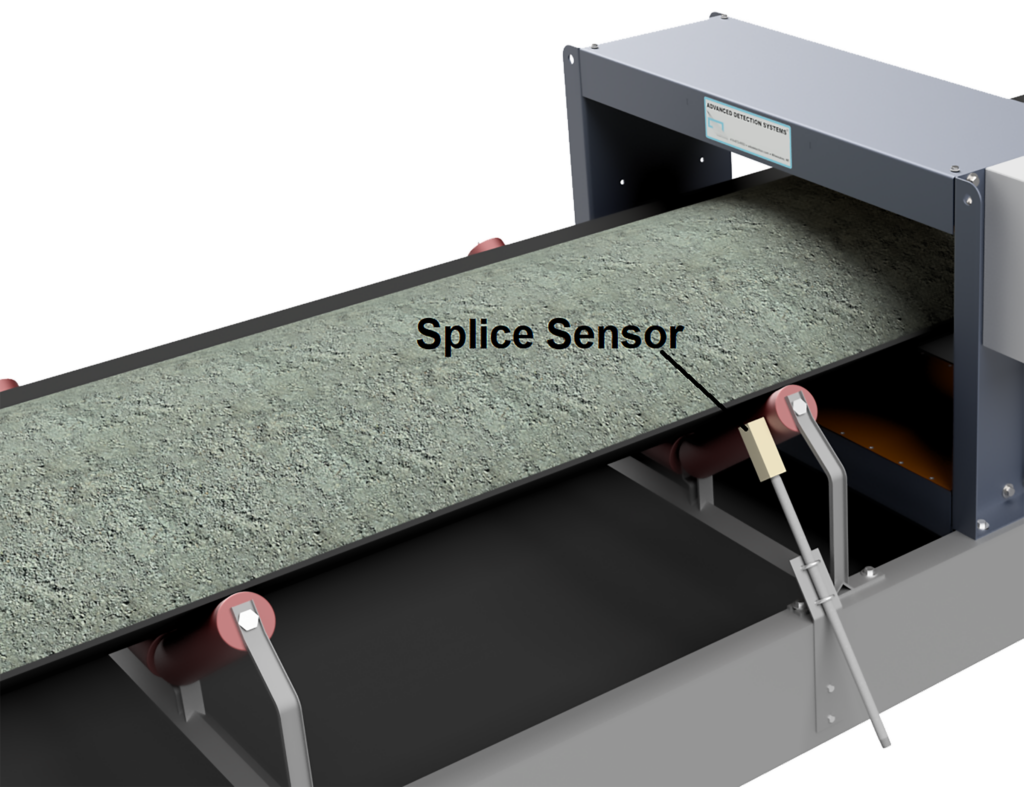

The splice sensor is an optional accessory used to accommodate ferrous belt splice and repairs.

The external remote control enclosure is an optional accessory used when the SurroundScan Protector HD is placed in a difficult to read position in your production stream.

Metal detectors used in environments below 40°F should be equipped with a Cabinet Heater to reduce condensation buildup and prevent the LCD screen from becoming lethargic or difficult to read in cold temperatures. The Cabinet Heater has a built-in thermostat to regulate temperature.