Metal detectors are used in food processing plants to detect Ferrous metal not removed by magnets and Non-Ferrous or Stainless Steel non-magnetic metals.

Metal Detection in the Food production Process

A study of the facility’s food production process is conducted to determine where metal could be introduced into the product stream. The study results in the formation and use of a Hazard Analysis Critical Control Point (HACCP) plan. The HACCP plan states where metal hazards exist, where and how metal detectors will be used to mitigate the hazard, and how proper use of the metal detector will be documented.

Common Food Processing Metal Detectors

Based on the source of ingredients, the food production process and the product’s packaging typical food processing metal detector configurations are conveyor mount, gravity fed and pipeline systems.

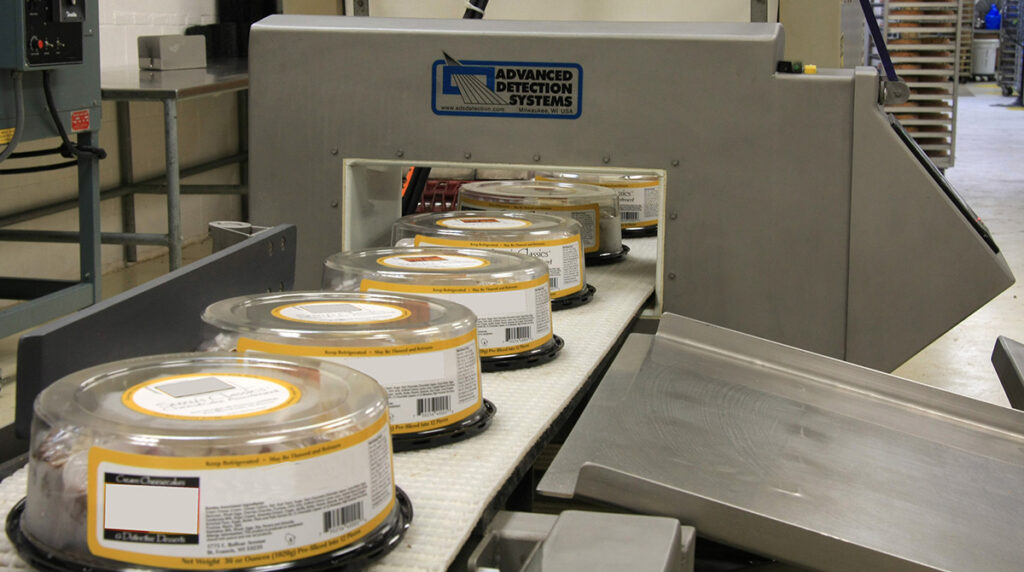

Conveyor Belt Food Processing Metal Detectors

A common placement of metal detectors in food processing are conveyor mounted detectors used to inspect packaged product that is sealed and safe from further metal contamination. The aperture of a conveyor mounted metal detector is sized to accommodate the largest package to be inspected. Depending on the food safety needs of the processor the metal detector can be set up to stop the conveyor while actuating a light and horn to alert nearby workers there has been a metal detection event or the detector can be used to actuate an automatic reject device upon detection of metal in the packaged food.

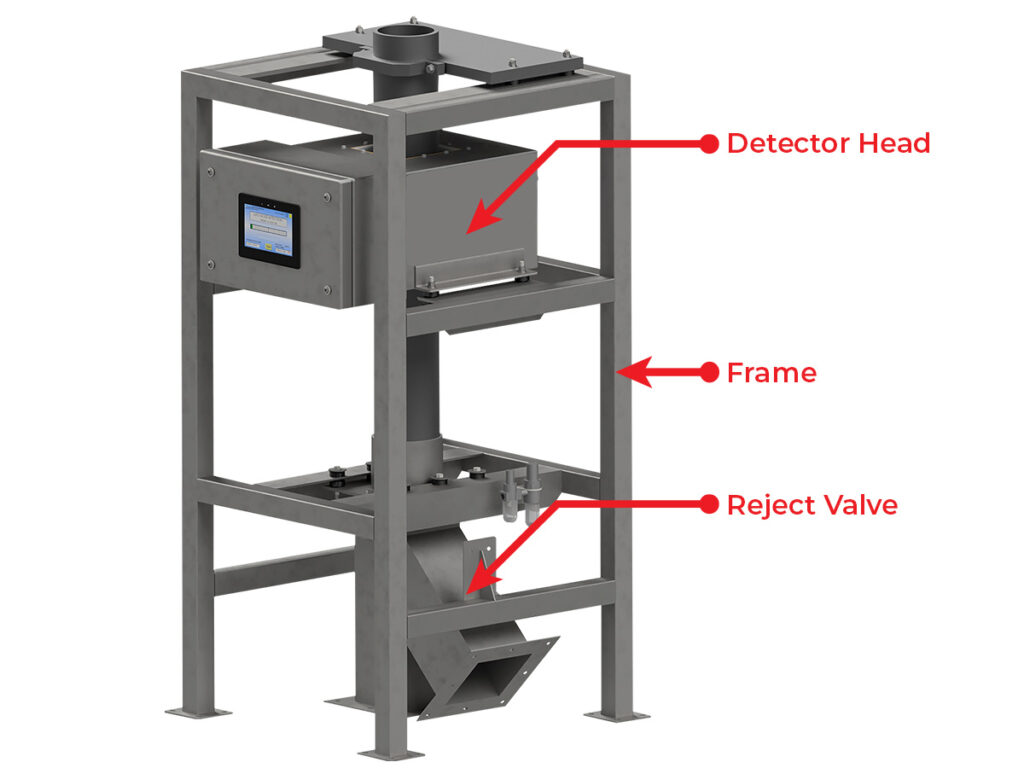

Gravity Drop Food Processing Metal Detectors

Metal detectors are sometimes used in addition to magnets early in the food production process. The goal is to ensure that no metal contaminants are in the ingredients that will be used to make the finished product. Food-grade gravity fed metal detectors with fast acting divert valves are used to inspect bulk ingredients upstream of production and final inspection of finished, ready to be packaged product. Gravity fed metal detectors can also be used after production of product but upstream of packaging if the food product is going be deposited or packed in conductive containers or packages that are not compatible with metal detector inspection.

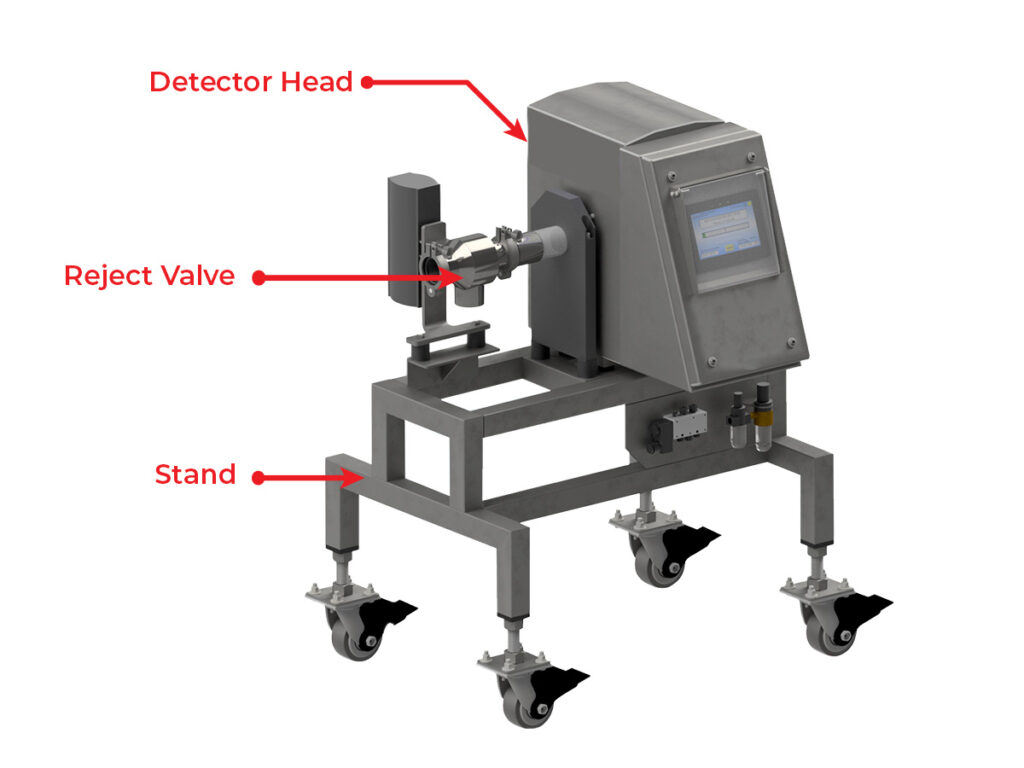

Pipeline Food Processing Metal Detectors

Pipeline metal detection systems are used in the food processing and packaging industry to inspect pumped, viscous products that are canned or deposited in containers that are closed with, or have, conductive components. Pipeline systems are space efficient and used with sanitary 3-way reject valves to divert small amounts of product when metal is detected.

Industrial & Food-Grade Metal Detectors from Advanced Detection Systems

Advanced Detection Systems, in business for 30 years has developed a reputation for manufacturing high quality, reliable metal detection equipment for a variety of food processing and industrial applications. With engineering, manufacturing, sales and customer service staff working side by side in our Milwaukee, WI facility we provide prompt, expert advice. We’re here to help, call us at (414-672-0553) or e-mail sales@adsdetection.com to discuss your application details and metal detection needs.