Metal Detection for Aggregate and Mining Applications

The Need for Metal Detection in Aggregate and Mining When a piece of metal gets into in your crusher or screen it can cause catastrophic damage. The resulting cost in downtime, labor and repairs needed to get back up and running again can be staggering. While magnets are still a very effective way of removing […]

Metal Detector Conveyor Options for Dry Packaged or Washdown Environments

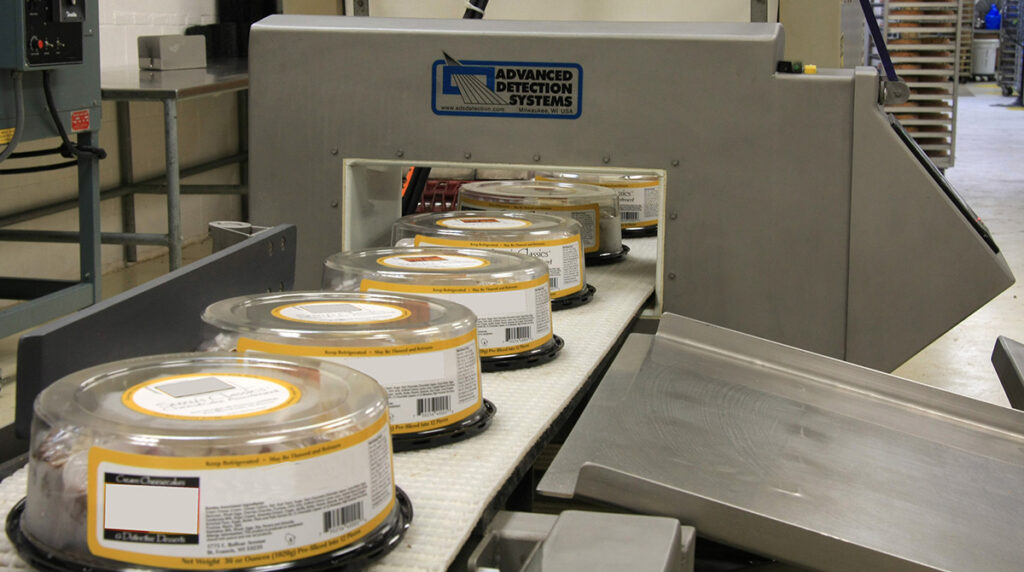

Conveyor metal detector in use in a commercial bakery How Metal Detectors are Used in Food Processing Introduction of metal contaminates can result from a variety of breakdowns common in the production process. Anything from processing equipment wear and tear, environmental hazards, to the harvesting of the product. Regardless of the source, metal must be […]

Metal Detection Solutions for Free-Flowing and Pumped Products.

For nearly 25 years, Advanced Detection Systems has been providing metal detectors for the food processing, packaging, pharmaceutical, nutraceutical and industrial applications. The ProScan Max® III conveyor metal detector system is ideal for running packaged and some larger loose products. However, when it comes to free-flowing granule sized products or pumped viscous liquid and semi-liquid […]

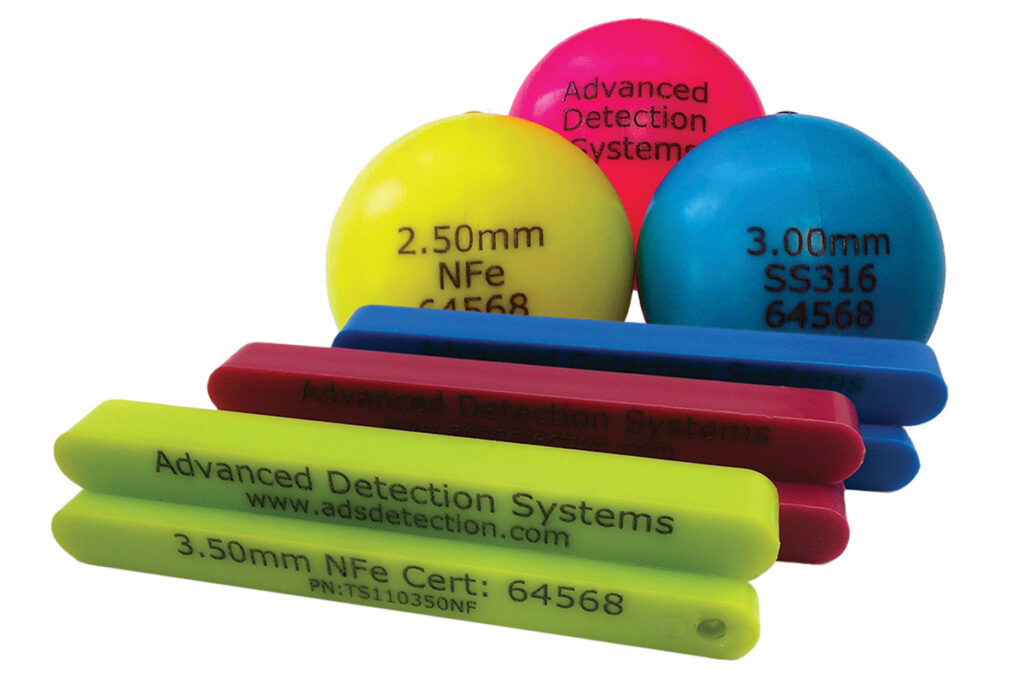

Metal Detector Test Wands: What They Are and How They’re Used

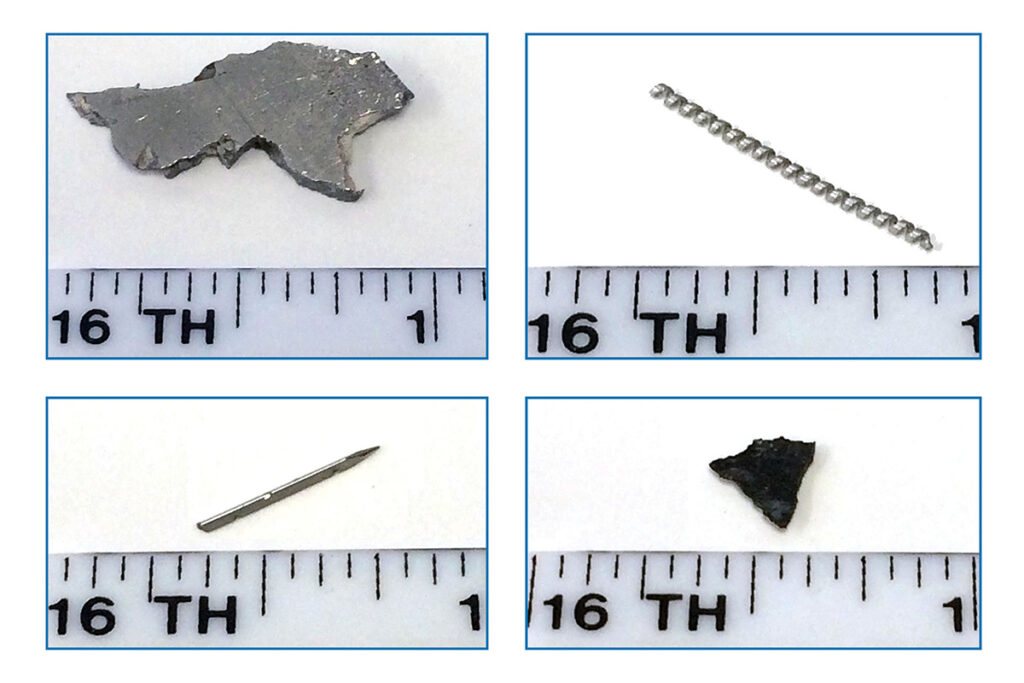

The Reason For Testing Your Product & Your Metal Detection Equipment The automation of the food processing industry guarantees that the food we eat will come in contact with various types of equipment, from automated pickers in the field, to conveyance, to processing and packaging equipment. Inevitably, equipment wears down and sometimes breaks, allowing for […]

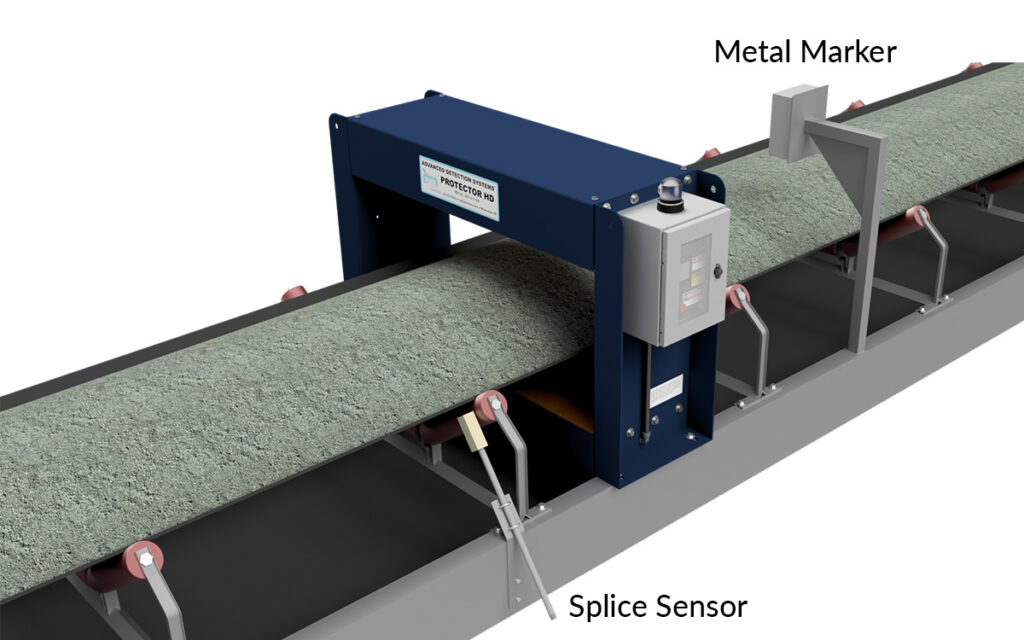

Metal Detector Accessories for Industrial Applications

Metal Detection for Aggregate & Mining Applications In industrial applications, metal detectors defend production lines from tramp metal and ferrous impurities that can damage your conveyors and processing equipment. Proper use of an industrial metal detector also improves the purity of your product. Today we’ll discuss three different optional accessories that will make your metal […]

How is Sensitivity in Metal Detection Measured

When you’re looking at metal detection systems for use in your product line, have you wondered “How small of a piece of metal will this detect?” “How do they determine that?” Good questions! How is Metal Detector Sensitivity Determined? Metal detector sensitivity is defined as: The smallest diameter sphere that can be detected, 100% of […]

How Does Metal Detection Work: The Basic Principles

The Theory Behind Metal Detection Balanced Coil All metals are either magnetically conductive, electrically conductive or both. When they enter an electro-magnetic field, they create a detectable disturbance or “signal”. Modern metal detectors operate on the balanced coil, full loop system which allows detection of this signal. A balanced coil consists of three coils looping […]

How Are Metal Detectors Used In Food Applications?

Food metal detectors detect and remove ferrous, nonferrous and stainless steel metals during food processing and packaging. Learn how and what the most common food processing metal detectors are.

How Is Product Contaminated with Metal Removed from the Food Production Process?

Metal detection is essential for the food processing and packaging industry. Not only do metal detectors protect the processing equipment, but they are also important in ensuring product purity and consumer safety. But have you ever wondered how metal is detected and removed during food processing? Metal detection is a two-step process. When metal has […]

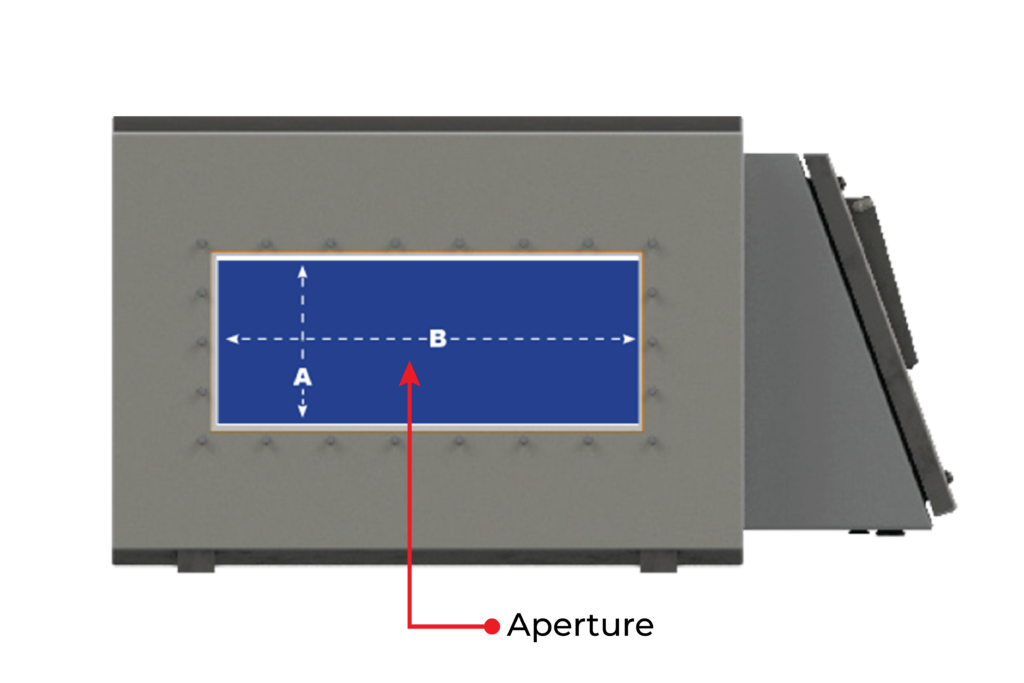

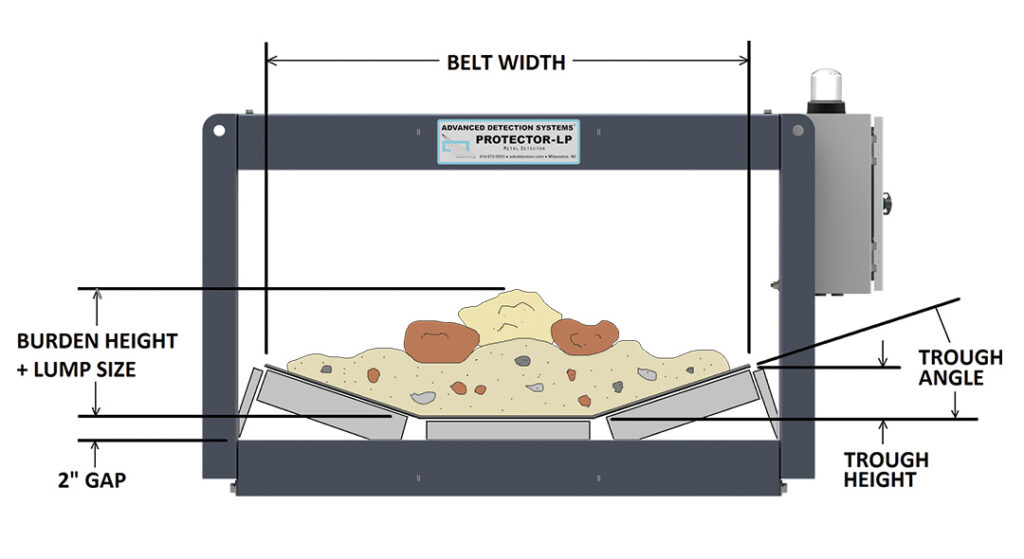

How to Size your Protector Metal Detector

Determining the proper height and width of your metal detector ensures that your application is getting the best possible sensitivity; both height and width play critical roles in sensitivity and ease of installation. The Protector metal detection system is designed to fit rails utilizing standard CEMA-approved rollers. In most instances, the detector will drop directly […]